|

80 foot Row Crop Boom with 30 inch on Center Spacing

The AB200DS has an 80 ft working width engineered for stability at high operating speeds.

The 80 ft span over 14% greater than the next largest pneumatic applicator on the market.

The 80 ft working width can also be paired with many controlled traffic patterns to minimize soil compaction.

|

|

Drop Tube Kit for Side Dress Application

The 80 ft application boom can be equipped with optional drop tubes to apply granular fertilizer into standing crops.

Side dressing the fertilizer below the crop’s canopy prevents leaf burn in standing crops and delivers mid-season nutrients to the improve crop yields.

The drop tubes can also be used for standard broadcast operation to further minimize the impact of wind on the application process.

|

|

Booms Clear up to 69 inches

The new AB200DS has a higher clearance boom for post-emergence application later in the growing season. This allows for application closer to the silking stage for corn plants, when the crop needs N and P for kernel development.

69 inches ground clearance is based on using 380/105R50 tires. Actual clearance may vary.

|

|

Hydraulic Boom Suspension

The hydraulic boom suspension allows for greater in field stability at higher operating speeds.

The boom height can also be controlled by the operator to improving contouring in uneven terrain.

|

|

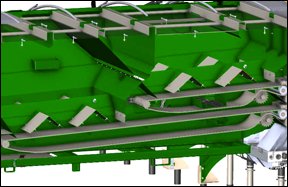

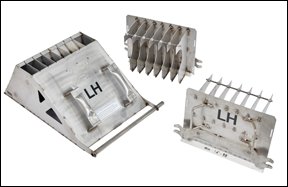

Factory Calibrated Air Booms

Air booms and funnels are factory calibrated. This makes for incredibly accurate application in the widest range of conditions.

|

|

Spring Loaded Tip Breakaway and Mid Boom Shear Bolt

In the unfortunate circumstance where the boom strikes an object or the ground there are two different safety system that protect the applicator.

The outer 5 feet has a spring-loaded breakaway tip that will return to working position automatically. If something is struck past the breakaway, the mid boom hinge has a shear bolt plate that will fail preventing severe boom damage.

|

|

Flat Fold System For Improved Cab Visibility

The booms fold tightly into the fame and lower into the transport cradles to maximize the operators field of view.

The new fold system reduces the number of moving parts while allowing a compact and consistent fold. The fold sensors on the main boom pivot and secondary fold hinge provide location feedback for the Parker IQAN controller to maintain a smooth sequence through the entire fold sequence.

|

|

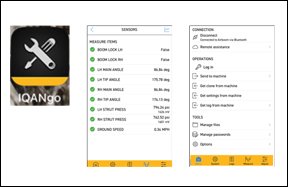

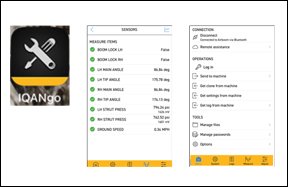

Boom Fold Remote Diagnostics

The boom fold system is equipped with a remote diagnostic tool. Boom fold diagnostics can be viewed by operator with an IOS or Android smart device. Select boom fold settings can be adjust from the app. In addition to settings and diagnostics the operator can also connect a technician to the boom fold system through the app in order to troubleshoot issues remotely.

|

|

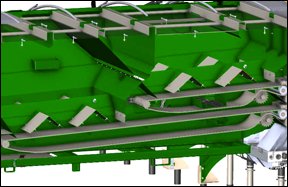

Hats For Even Load Distribution During Emptying

Each metering chain is covered by a series of stainless steel hats that prevent product bridging and evenly distribute the load in the hopper. This improves the accuracy of the metering system and increases the life of the metering chain and the metering drive system. By evenly metering the product out of the hopper this system also improves weight distribution through the applicator.

|

|

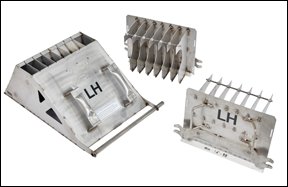

Calibrated Metering Funnels

The AB200DS has left and right metering funnels which accurately direct the right amount of material through the Venturi into each tube on the air boom. The main funnel is combined with upper sections that guide the material off of the chain into the main funnel. This ensures that the system continue to deliver the right amount of material to each boom outlet even on hill sides and rough terrain.

|

|

Easy Clean Out Funnels

The hopper can be cleaned out and calibrated using the easy clean out funnels. The funnels are conveniently mounted on the side of the hopper and lock into the frame below the hopper conveyor. There’s a channel in the funnel to hold a bucket handle to catch material for calibration testing. The applicator includes a density scale and hand held digital weigh scale for easy calibration.

|

|

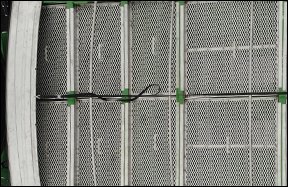

Stainless Steel Bin Screens

The stainless steel bin screens prevent large clumps of fertilizer and foreign material from being fed into the system and causing material flow issues at the funnel or through other systems.

The bin screens are recessed into the hopper for quicker loading times.

|