Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

Salford Halo - HSD

|

Halo - HSD

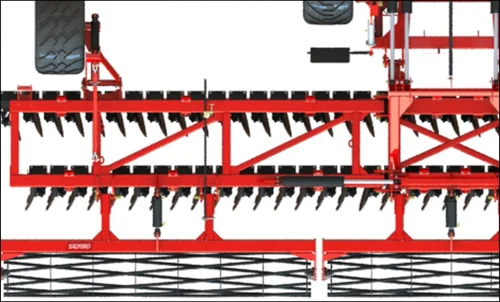

The HALO HSD is engineered for level operation at speed and with the clearance needed for tough conditions. HALO HSD’s individually mounted blades allow for maximum residue and soil flow, while the angled blade mounting arms are designed to keep the HALO HSD at depth in hard ground. HALO HSD has advanced hydraulic systems that are simple to operate. Fore/aft leveling, active down pressure, single point depth control, and finishing systems all have hydraulic adjustment that is easy to use. |

|

HALO HSD MODEL OVERVIEW

The HALO HSD’s front row of 22 inch, smooth concave blades maximize ground penetration and residue sizing. The blades are tipped under to keep the machine engaged in hard soil. Front Row of Blades: |

|

The rear row of 22 inch, notched blades continue to size residue and ensure the second row of blades turns continuously in the loose soil created by the front row of blades. The blades are tipped under to keep the machine engaged in hard soil. Rear Row of Blades: |

|

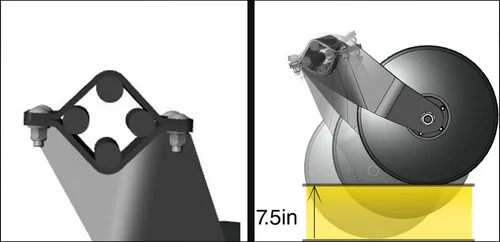

HALO blade mounts are 5/8 inch AR400 steel adds to the toughness and abrasion resistance of the HALO. The blade and arm are on a rubber torsion mount which give the blade up to 7.5 inches of vertical travel for maximum obstacle protection. |

|

HALO’s proprietary five bolt hub is maintenance free, equipped with a double tapered roller bearing and protected by a multi-lip seal designed specifically for Salford. The hub can be rebuilt. |

|

HALO HSD’s adjustable dirt shield is designed to improve the machine’s field finish. The shield can be set to float and the parallel linkage allows it contour uneven terrain. The operator is also able to lock the dirt shield in multiple positions to tailor the field finish. |

|

HALO HSD comes with a 23 inch cage roller finishing system. The heavy duty roller is designed to size soil clods, condition residue and level the field surface. |

|

The 23 inch cage roller is carried by a heavy duty disc style bearing with a wide inner race for proper alignment and maximum durability. |

|

The HALO HSD is now available with an OTICO Wave-Profile FARMFLEX® roller. This OTICO rubber roller’s unique wave design with molded cleats is designed to trap moisture and reduce crusting. The semi-pneumatic roller is engineered to break up soil clods and gently firm soil improving seed to soil contact when preparing seedbeds with the HALO HSD. The pliable rubber form flexes as it crosses the ground to help shed soil and residue that may stick to the finishing attachment. The flexible design also acts as obstacle protection to help prevent damage to the roller and roller frame when the unit hits rocks in the field. |

|

HALO uses a forward folding design for narrow transport making it safer and easier to travel, even on narrow, populated roads. |

|

600/50R22.5 tires provide maximum floatation in the field and make for safe transport on the way to the field and between farms. |

|

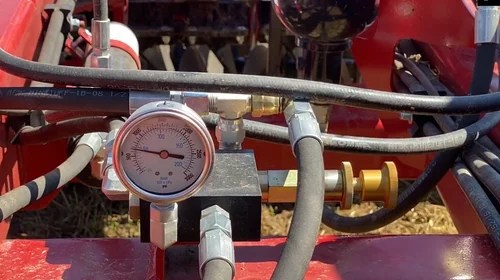

HALO uses single point depth control for the machines operating depth, making for fast, easy adjustments to the tillage action. The rear finishing system also uses single point hydraulic control to regulate down pressure. This allows operators to quickly adapt to field conditions. |

|

HALO’s wings can be run with active down pressure. This keeps the machine operating level from side to side and ensures wings stay engaged in tough conditions. |

|

HALO’s fore/aft pitch can be adjusted from the cab and set to float or neutral during operation. HALO’s ability to be ran in neutral allows the machine to run level in a greater variety of field conditions for a superior finish. The fore/aft hydraulic system is protected by a hydraulic accumulator while running in neutral. |

|

HALO’s mainframe has large pitch indicator that can be easily seen from the cab. |

|

HALO’s rectangular main frame is 6 inch by 6 inch tubular steel, 3/8 inch thick. All frame members are capped for maximum durability and longevity. The front and rear mainframe bars are designed to carry multiple different tillage modules. HALO’s tongue is 6 inch by 8 inch on 2 piece frame models, and 6 inch by 10 inch on 3 piece frame models. |

|

Salford implements feature a color coded operator’s convince center that manages and protects the hydraulic hoses and lighting connection. The operator’s manual is also housed here in a weather proof container. Hydraulic hose grips are color coded to make for fast, easy connection to the tractor |

|

HALO’s rectangular main frame is 6 inch by 6 inch tubular steel, 3/8 inch thick. All frame members are capped for maximum durability and longevity. The front and rear mainframe bars are designed to carry multiple different tillage modules. HALO’s tongue is 6 inch by 8 inch on 2-piece frame models, and 6 inch by 10 inch on 3-piece frame models. |

|

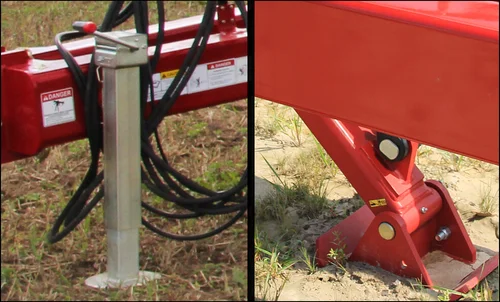

HALO 2 piece frames use an 8,000 lb manual jack. HALO 3 piece frame models use a hydraulic jack with a manual ball value. |

|

High Speed and Highly Durable

|

|

Superior Leveling

|

Easy to Operate

|

Low Maintenance Design

|

Standard Features

|

|

Tires

|

|

Finishing Options

|

| HALO | |||||

|---|---|---|---|---|---|

| Configuration | Specifications | ||||

| Model Size | 20' (6.096 m) | 25' (7.62 m) | 30' (9.144 m) | 35' (10.668 m) | 40' (12.192 m) |

| Approximate Weight (lbs) | 15,440 | 19,300 | 26,100 | 27,800 | 29,100 |

| Driving Interval | 19 ft. 1 in. | 24 ft. 1 in. | 29 ft. 2 in. | 34 ft. 1 in. | 39 ft. 1 in. |

| Concave Blades | 48 | 60 | 72 | 84 | 96 |

|

Transport Height Rollers Extended Rollers Retracted |

12 ft. 5 in. 13 ft.6 in. |

12 ft. 6 in. 13 ft. 7 in. |

13 ft. 10 in. 14 ft. 11 in. |

12 ft. 11 in. 14 ft. 0 in. |

13 ft. 3 in. 14 ft. 4 in. |

|

Transport Width Rollers Extended Rollers Retracted |

11 ft.8 in. 11 ft.3 in. |

11 ft.8 in. 11 ft.3 in. |

13 ft.4 in. 11 ft.11 in. |

13 ft.4 in. 11 ft.11 in. |

13 ft.4 in. 11 ft.11 in. |

| Frame Sections | 2 | 3 | |||

| Mainframe structure | 6 in. x 6 in. tubular steel | 6 in. x 6 in. tubular steel | |||

| Hitch Structure | 6 in. x 8 in. tubular steel | 6 in. x 10 in. tubular steel | |||

| Tires, Mainframe | 600/50-22.5, 10 bolt hub | 600/50-22.5, 10 bolt hub | |||

| Tires, Wings | N/A | 600/50-22.5, 10 bolt hub | |||

| Drawbar Hitch | CAT 4 | CAT 5 | |||

| Hitch | 8,000 lbs manual jack | Hydraulic jack with manual ball value | |||

| Hydraulic Remote Valves Required | 4 | 5 (includes hydraulic jack) | |||