Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland GENESIS® T8 Series with PLM Intelligence™ - T8.435 SMARTTRAX™

|

RATED HORSEPOWER – ISO – ECE R120, 2000 RPM (HP (KW)) 380 (279) AUTO COMMAND™, 396 (295) ULTRA COMMAND™ MAX. EPM HORSEPOWER** – ISO – ECE R120, 1800 RPM (HP (KW)) 435 (320) | |

MORE POWER AND PRODUCTIVITYChoose between models ranging 250 to 396 rated horsepower with an enormous 40% torque rise, plus up to an additional 71 boosted horsepower from the Engine Power Management system. | |

CAB ENHANCEMENTSRedesigned cab and controls, including the most functional and customizable armrest and display you’ll find, add new levels of comfort and convenience to your long and hectic days. | |

MAXIMUM VERSATILITYThe new IntelliView™ 12 display and Sidewinder™ Ultra armrest are second to none! We built your control package around the revolutionary idea that customer adjustments should come standard to increase your operator efficiency. | |

CONNECTED MACHINEReduce downtime and keep operators in the field with added connectivity and support features. With remote viewing capabilities, you can access the in-cab IntelliView™ 12 display to help identify problems and gain deeper insights. |

SIDEWINDER™ ULTRA: THE ULTIMATE ERGONOMIC FARMING EXPERIENCE.GENESIS® T8 tractors offer sophisticated features that are easy and intuitive to access. The SideWinder™ Ultra armrest hosts all key controls. Throttle, transmission and hydraulics. Everything you need to control is intuitively selected. More advanced features can be quickly accessed. | |

CUSTOMIZABLE BUTTONS

| |

ADJUSTABLE SIDEWINDER™ ULTRA ARMRESTThe SideWinder Ultra armrest can be adjusted to suit your specific requirements. Two manual levers adjust both the height and fore-aft position of the armrest for enhanced ergonomic operation. |

THE POWER AND EFFICIENCY YOU’VE COME TO EXPECT FROM NEW HOLLAND.The 8.7 liter FPT Industrial Cursor 9 engines, featuring ECOBlue™ HI-eSCR 2 technology, continue to set the standard for engine performance, dependability and efficiency yet still meet the latest Stage IV emission regulations. This is paired with long, 600 hour main service intervals. | |

ECOBLUE™ HI-ESCR 2 EXPLAINED

| |

POWERED BY FPT INDUSTRIALNew Holland is not alone when it comes to Stage IV Final technology. They can draw on the experience of their in-house engine development group: FPT Industrial. Pioneers: Fiat invented Common Rail technology in the 1980s and brought it to the masses in 1997 on the Alfa Romeo 156. They were the very first to introduce it on agricultural machines on the TS-A tractor. Pioneering. Always. Cleaner: For the ninth consecutive year, CNH Industrial has topped the Dow Jones Sustainability World and Europe indexes for the Industrial Engineering sector. Cleaner Everywhere. Proven: FPT Industrial has pioneered SCR technology since 1995 and has already produced over 1 million SCR engines during the last eight years for the agricultural, construction and haulage industries. Reliability. Confirmed. | |

| |

ALL THE POWER YOU NEED ALWAYS AVAILABLEHere at New Holland we’re passionate about transient response. You might think so what. But it’s your productivity guarantee. Put simply, as your Cursor 9 engine only breathes clean fresh air it can react even quicker when placed under load. Significantly quicker in fact. Transient response. We’ve got it covered. |

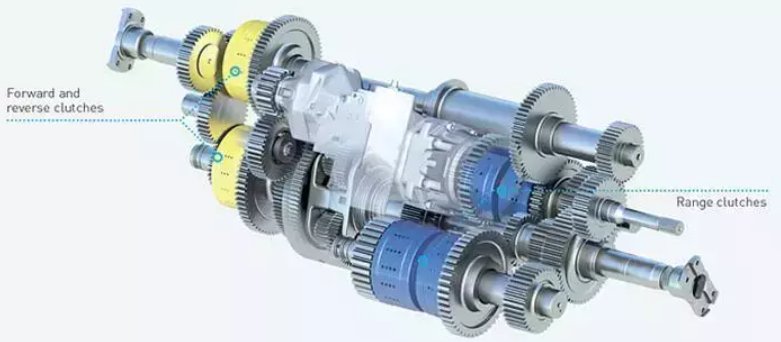

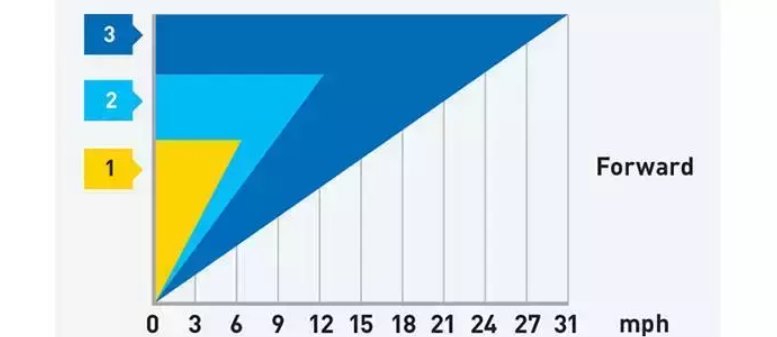

ALL THE POWER AND PERFORMANCE YOU COULD ASK FOR, DELIVERED EFFICIENTLYUltra Command™ full powershift transmissions match proven mechanical efficiency to New Holland ease of control. The result? A transmission that is easy to set up and operate with a speed to perfectly match every application. It’s one of the most efficient full powershift transmissions available today. Available on the T8.320 – T8.435 models, the CommandGrip™ handle provides fingertip access to automated features, including Ground Speed Management. Choose between an 18 x 4, 19 x 4 (25 mph ECO or 31 mph) or 21 x 5 (25 mph or 31 mph) direct drive transmission. The Auto Command™ CVT transmission benefits from four direct-drive points with 100% mechanical efficiency. Advanced double-clutch control further enhances efficiency. Active stop-start — when the tractor is brought to a standstill, the transmission prevents the tractor from moving backwards or forwards, even with a heavy load. | |

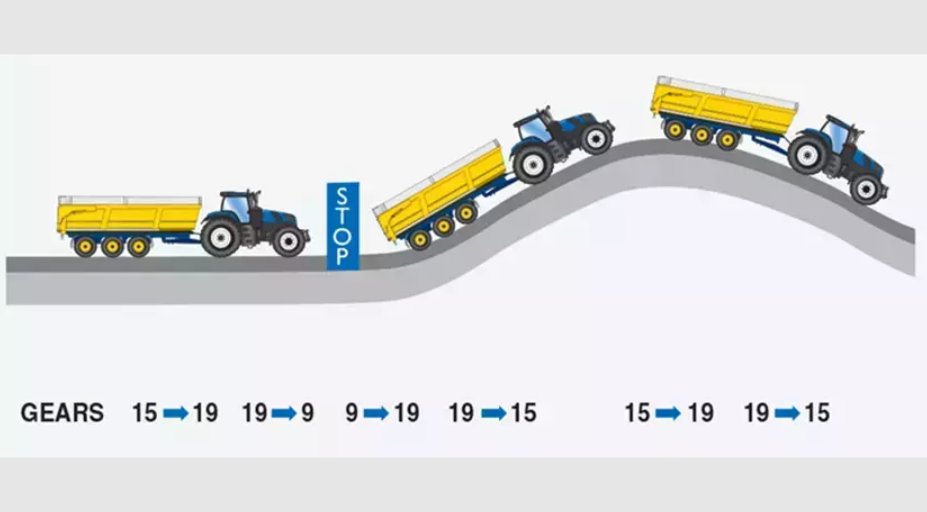

GSM. INTELLIGENT AUTOMATION.New Holland Ground Speed Management, GSM, is more than just an automated transmission shift system. With CVT-like functionality, it uses a combination of data relating to engine load, forward speed and operator setting, to manage both engine and transmission speeds to optimize performance and economy. Simple to set up and extremely efficient, GSM is well proven and dependable. | |

FIXED FORWARD SPEED? GSM TAKES CARE OF IT.

| |

FULL COMMAND IN TRANSPORT

| |

GEAR AND SPEED AT A GLANCE

| |

ULTRA COMMAND™ POWERSHUTTLE

| |

INNOVATIVE AUTO COMMAND™ TRANSMISSION OFFERS ADVANCED NEW HOLLAND FEATURES.

| |

THREE ADJUSTABLE TARGET SPEEDS FOR EVERY NEED

| |

TAILORED TRANSMISSION SETTINGSThe multi-award winning Auto Command™ continuously variable transmission now features a three-stage acceleration and deceleration setting. The ‘soft’ setting is suitable for gentle direction changes, perfect during high speed transport or when working on slippery surfaces. The standard setting has been designed for normal field activities. The super-fast aggressive setting is ideal when near instantaneous direction changes are required. | |

ACTIVE STOP STARTA key safety feature of Auto Command™ is Active StopStart. When the tractor is brought to a standstill, the transmission prevents the tractor moving backwards or forwards, even with a heavy load. When the transmission takes up drive there is no risk of roll back on steep inclines. For safe parking, an electronic brake is easily engaged via the shuttle lever. | |

BALANCING FUEL ECONOMY AND PRODUCTIVITYWhen working in Auto and Cruise modes, use the droop control setting, which can be adjusted in the transmission setup screen of the IntelliView™ 12 display or by accessing this setup screen via the quick key button on the SideWinder™ Ultra armrest, to limit the upper engine speed used to achieve the desired forward speed. The result: you reach target speed at much lower engine revs, saving you fuel. In PTO mode, use droop control to regulate the acceptable reduction in PTO speed before forward speed is reduced. |

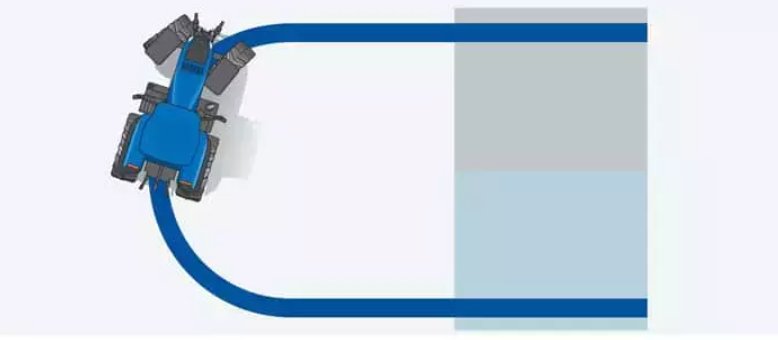

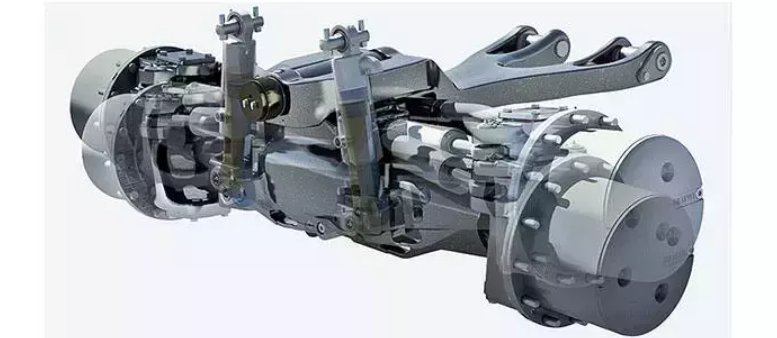

TRACTION WITHOUT QUESTION.The GENESIS® T8 range has the longest wheelbase in the segment. Ultra Command™ models boast a 136” (345.4 cm) wheelbase, and 140” (355.6 cm) on the T8.435. That is a full 10” (25.4 cm) longer than the nearest competitor. A longer wheelbase means greater stability at high transport speeds, is easier to ballast with better weight transfer, and more traction for demanding heavy drawbar applications. The GENESIS® T8 range features up-rated front axles in line with its 20 ton (18.1 MT) gross vehicle weight, which means that you can work with even heavier attachments with ease. Terraglide™ front axle suspension is a standard feature and its twin dampers and accumulators deliver a silky smooth ride. The engine and subframe have been designed to maximize turning performance, so that the front wheels can nip in tight against the sculpted sump and tombstone for tight turning. |

NEW HOLLAND GENESIS® T8. A WHEELED ADVANTAGE OVER

|

BRAKE ASSIST FOR TIGHTER TURNING

|

SAFE BRAKING TECHNOLOGY

|

HEAVY DUTY AXLES FOR HEAVY DUTY PERFORMANCE

|

CUSTOMSTEER™ VARIABLE RATIO STEERING

|

ADVANCED TRACTION MANAGEMENT

|

TERRAGLIDE™ FRONT AXLE SUSPENSION

|

TIRE PRESSURE MONITORING SYSTEMOperators can check the pressure of up to 16 tires with the tire pressure monitoring system (TPMS). Sensors on each tire transmit via wireless to an antenna within the cab roof. For each tire the operator can input the ideal working pressure for a specific task. The pressure values are saved against the implement name within the IntelliView™ 12 monitor, so you only need store settings once. An on screen warning then alerts the operator if the pressures are not in line with the ideal value. The TPMS benefits operational efficiency, warning if the pressures are set incorrectly, and provides an early warning of any potential punctures on a trailer for example. |

SEMI-ACTIVE COMFORT RIDE™ CAB SUSPENSIONThe optional Semi-Active cab suspension system uses a network of sensors which monitor cab position, velocity and acceleration, together with cab pitch and roll to automatically adjust the individually controlled hydro-pneumatic rear cab suspension struts to ensure the smoothest ride. The operator can select from three different modes normal, soft - used to absorb large bumps, ideal when working in soft and rough terrain at slow speeds or hard - ideal when working at higher speeds and during road transport. |

HYDRAULIC POWERAll GENESIS® T8 tractors are fitted with an advanced Closed Center Load Sensing hydraulic system as standard. 59 gpm (223.3 L) is the standard flow, which is enough to power the majority of farming applications. For the most hydraulically demanding customers, the MegaFlow™ option offers an impressive 86 gpm (325.5 Lpm) of flow. If that wasn’t enough, New Holland has engineered the CCLS system to operate at peak efficiency. |

HYDRAULIC REMOTE VALVE MANAGEMENT

|

QUICK AND SIMPLE FLOW CONTROL SETTING

|

UP TO 9 CONFIGURABLE ELECTRONIC REMOTES

|

|

Engine* |

FPT Cursor 9 |

|

Rated horsepower – ISO – ECE R120, 2000 rpm (hp (kW)) |

380 (279) Auto Command™, 396 (295) Ultra Command™ |

|

Max. EPM horsepower** – ISO – ECE R120, 1800 rpm (hp (kW)) |

435 (320) |

|

Max. horsepower – ISO – ECE R120, 1800 rpm (hp (kW)) |

417 (307) |

|

PTO HP (SAE) (hp (kW)) |

315 (235) Auto Command™, 345 (257) Ultra Command™ |

|

Engine Type |

Tier 4B Final with ECOBlue™ SCR HI–eSCR system (selective Catalytic Reduction) |

|

Cylinders / Valves / Displacement (cu. in. (L)) |

6 / 24 / 531 (8.7) |

|

Aspiration |

Single Turbocharger w/eVGT (variable geometry turbo) |

|

18 x 4 Ultra Command™ Full-Powershift (25 mph (40 kph)) |

– |

|

19 x 4 Ultra Command™ Full-Powershift (25 mph (40 kph) ECO or 31 mph (50 kph)) |

– |

|

21 x 5 Ultra Command™ Full-PowerShift (25 mph (40 kph) ECO or 31 mph (50 kph)) |

Standard |

|

Auto Command™ Continuously Variable Transmission (25 mph (40kph)) |

Optional |

|

Auto Command™ Continuously Variable Transmission (31 mph (50kph)) |

– |

|

Alternator / Battery |

240 amp / 12-volt battery |

|

Rear axle dimension standard/optional (in. (mm)) |

– |

|

Rear axle length (in. (mm)) |

– |

|

Terraglide™ front axle suspension |

Optional |

|

MFD tread adjustability (in. (mm)) |

– |

|

Track Spacing (center to center) (in. (mm)) |

76-152 (1930-3861) |

|

System type |

Pressure-flow compensating (PFC) |

|

Standard pump flow (gpm (Lpm)) |

59 (224) |

|

MegaFlow™ option (gpm (Lpm)) |

86 (325) |

|

Rear linkage category (lbs. (kg)) |

Cat HD IVN/III |

|

Cat III/IIIN Lift capacity 43" links / 38" links, 4" rear axle (lbs. (kg)) |

– |

|

Cat III/IIIN Lift capacity 43" links / 38" links, 4.5" rear axle (lbs. (kg)) |

– |

|

Cat IVN/III Lift capacity 43" links / 38" links, 4.5" rear axle (lbs. (kg)) |

– |

|

Cat HD IVN/III, 5" rear axle (lbs. (kg)) |

19,900 (9026) |

|

Front linkage lift capacity (24 in. (610 mm) in front of ball ends) (lbs. (kg)) |

12,800 (5810) |

|

Front PTO and shaft size (in. (mm)) |

1000 rpm, 1.375 (34.9), 21 spine |

|

Fuel Tank (gal. (L)) |

163 (617) Auto Command™, 179 (678) Ultra Command™ |

|

Diesel Exhaust Fluid (DEF) Tank (gal. (L)) |

26 (99) |

|

Wheelbase length (in. (mm)) |

140 (3555) |

|

Cab sound level (dBA) |

69 |

|

Volume-size (cu. ft. (cu. m)) |

109.5 (3.1) |

|

Glass (sq. ft. (sq. m)) |

68.5 (6.4) |

|

Estimated average standard weight*** (lbs. (kg)) |

35,788 (16,233) |

|

Max Ballasting (lbs. (kg)) |

41,170 (18700) |

ENGINE POWER MANAGEMENT EXPLAINED

ENGINE POWER MANAGEMENT EXPLAINED