Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland Roll-Belt™ Round Balers - Roll-Belt™ 460

|

DIAMETER (IN. (CM)) 36-72 (91.5-182) WIDTH (IN. (CM)) 46.5 (118) | |

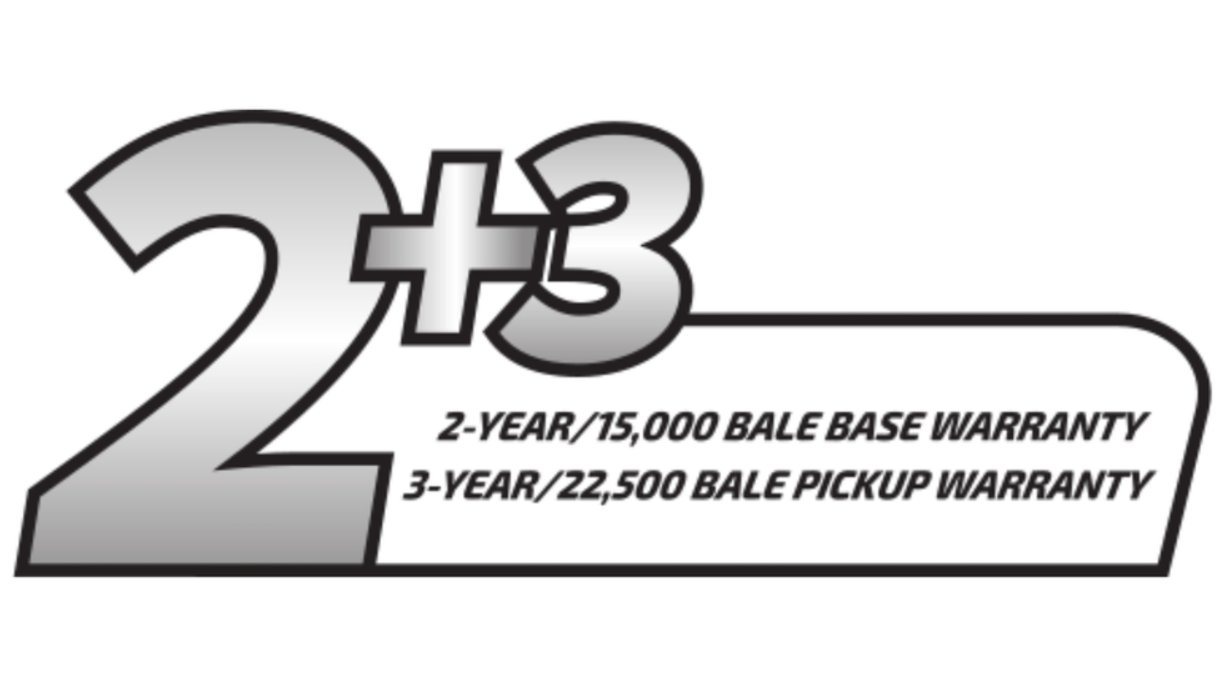

BALE WITH THE BESTTo help lower your operating costs, the Roll-Belt design can build the industry’s densest bales. Additionally, all models are backed by an industry-leading 2-year/15,000-bale base warranty and a 3-year/22,500-bale pickup warranty. | |

INNOVATION THAT PACKS PAYBACKDurable pickups, smooth feeders, and heavy-duty rolls partner with short, tough belts for fast core starts and uniform bales in any crop type. | |

DESIGNED WITH YOU IN MINDStandard features like banked grease zerks, hydraulic pickup lift, a premium cut-out clutch and wide-opening shields ensure that you stay productive. | |

PRECISION TOOLS THAT IMPROVE PRODUCTIVITYPrecision solutions, like IntelliBale™ baler automation, in-cab density control and factory-installed moisture sensing help you produce better bales. |

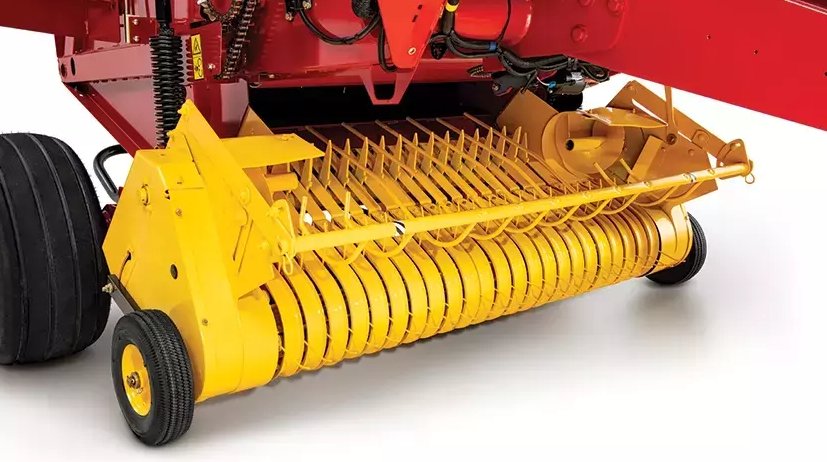

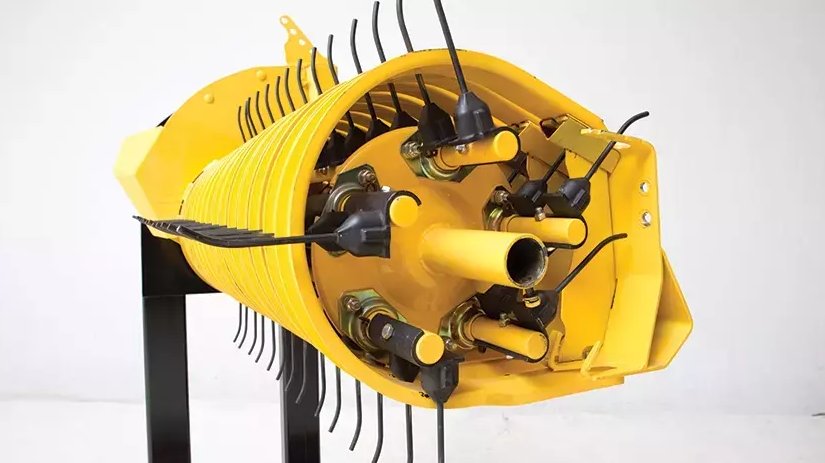

LEAVE NOTHING BUT BALES BEHINDBuilding perfect square-shouldered bales starts with a pickup that delivers a clean sweep and reliable feeding. That’s why all Roll-Belt™ pickups are designed to be tough, with strong tine bars and intermediate reel supports that resist bending. They deliver a clean sweep with a double-cammed reel drive, a heavy-duty steel roller and a tine windguard that improve both crop flow and capacity for positive, trouble-free feeding. | |

PROVEN SUPERSWEEP™ PICKUP

| |

STANDARD FOUR-BAR 1.8M PICKUP

| |

HEAVY-DUTY FIVE-BAR 1.8M OR 2.0M PICKUP

| |

ACTIVESWEEP™ FEEDER AND AUGERS

|

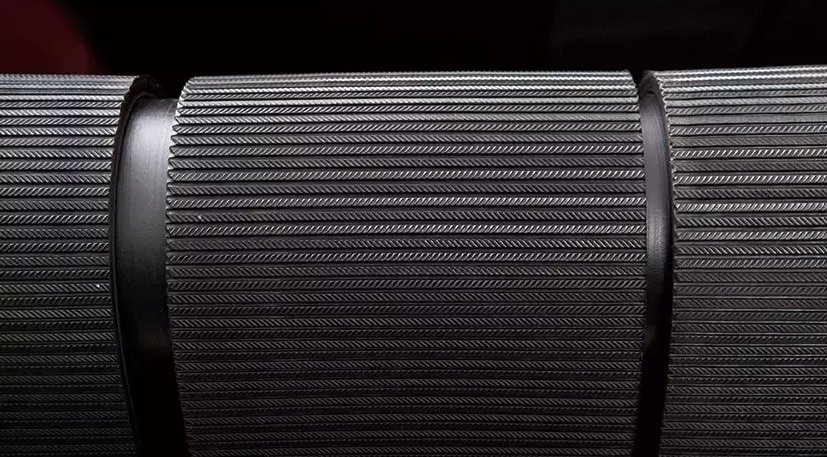

INNOVATION THAT PACKS A PAYBACKThe Roll-Belt™ design utilizes heavy-duty steel rolls in the front of the baler and in the floor of the bale chamber. These rolls are combined with short, tough belts in the back to deliver fast, consistent core formation and tight, uniform bales regardless of the crop you’re baling. Saving you both time and money, this proven combination packs more of your valuable crop into each bale to form some of the densest bales in the industry. | |

HOW IT WORKS

| |

SIMPLE DENSITY CONTROLS

| |

MINI-ROUGH-TOP (MRT) BELTS WITH STANDARD-DUTY LACING OR HEAVY-DUTY PLATE LACING

| |

PREMIUM ENDLESS BELTS

|

DESIGNED WITH YOU IN MINDTo ensure that you stay productive, Roll-Belt™ round balers have a wide array of standard features designed with you in mind. In fact, even base models come with more standard features than the competition. From an industry-leading warranty that provides a 2-year/15,000-bale base warranty and a 3-year/22,500-bale pickup warranty to simple features that increase your productivity, like banked grease zerks and a standard hydraulic pickup lift, you can rest assured that you’ll be ready to roll as soon as the conditions are right. | |

WORRY ABOUT THE WEATHER, NOT YOUR WARRANTY

| |

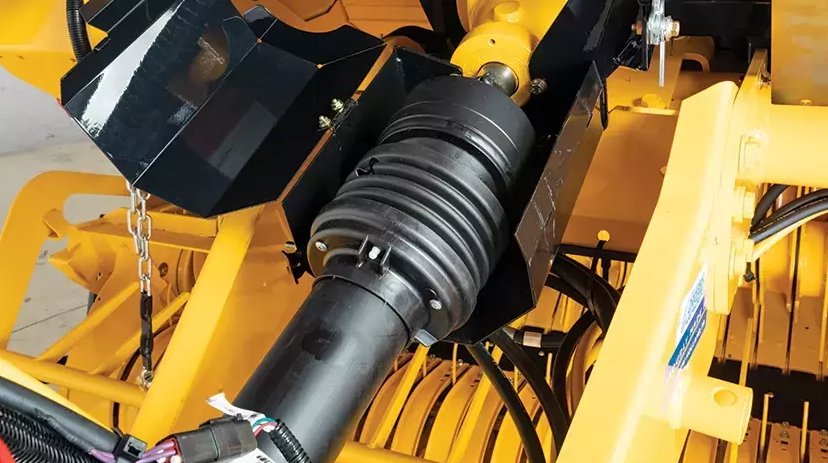

ALL POWER. NO HASSLE.

| |

WIDE-OPEN SERVICING

| |

FAST AND SIMPLE DAILY MAINTENANCE

| |

HITCHED TO BENEFITS

| |

ORGANIZED CONNECTIONS

|

|

Diameter (in. (cm)) |

36-72 (91.5-182) |

|

Width (in. (cm)) |

46.5 (118) |

|

Weight (lbs. (kg)) |

400-2,300 (181-1043) |

|

Density Pressure |

Adjustable |

|

Overall length, tailgate closed (in. (cm)) |

189 (481) |

|

Overall height, tailgate closed (in. (cm)) |

113 (287) |

|

Shipping weight (lbs. (kg)) |

6553 - 7174 (2972 - 3254) |

|

Floor roll (ActiveSweep™) (in. (cm)) |

8 (20.3) |

|

Floor roll (All others) (in. (cm)) |

12 (30.5) |

|

Forming rolls (in. (cm)) |

3 rolls, 10 (25.4) |

|

Stripper roll (in. (cm)) |

10 (25.4) |

|

Starter roll (in. (cm)) |

6.6 (17) |

|

Bottom tailgate idler roll (in. (cm)) |

5.5 (14) |

|

Factory-installed moisture sensor (7-60% range) |

Optional |

|

Number of belts |

6 |

|

Belt width (in. (cm)) |

7 (18) |

|

Belt length (in. (cm)) |

421 (1068) |

|

Mini Rough Top with standard-duty lacing |

- |

|

Mini Rough Top with heavy-duty plate lacing |

Optional Hay Special |

|

Premium endless belts with sealed edges |

Silage Special, Bale-Slice, SuperFeed, & CropCutter |

|

Twine application |

Dual twine arms |

|

Twine control |

Automatic, electric |

|

Twine box |

6 active balls |

|

Additional twine storage |

4 balls (2 per side) |

|

Net Wrap |

EdgeWrap™ net wrap system, 3 roll capacity |

|

Auto-Wrap™ II monitor |

- |

|

Bale Command™ II PLUS monitor |

Standard |

|

ISOBUS less display |

Optional |

|

ISOBUS & IntelliView™ IV display |

- |

|

11L-14 |

- |

|

31x13.5-15 |

Hay Special & Silage Special |

|

480/45-17 |

Standard: SuperFeed™ & CropCutter® ; Optional: Hay Special & Silage Special |

|

21.5L-16.1 |

Optional |

|

550/45-22.5 |

Optional |

|

560/45-R22.5 |

Optional |

|

Minimum PTO horsepower (hp. (kW)) |

70 (52) |

|

PTO speed (rpm) |

540 or 1,000 |

|

Premium cut-out clutch |

Standard |

|

Hydraulic remote requirement |

1 to 4 |

Pickup Specifications - SuperSweep™ 1.5M 4-bar Pickup | |

|

Models |

- |

|

Width, inside/tine-to-tine (in. (cm)) |

- |

|

Width, outside/flare-to-flare (in. (cm)) |

- |

|

Tine spacing (in. (cm)) |

- |

|

Tine bars |

- |

|

Number of tines |

- |

|

Reel diameter (in. (cm)) |

- |

|

Pickup protection |

- |

Pickup Specifications - Standard-Duty 1.8M 4-bar Pickup | |

|

Models |

Hay Special |

|

Width, inside/tine-to-tine (in. (cm)) |

71 (180) |

|

Width, outside/flare-to-flare (in. (cm)) |

79 (202) |

|

Tine spacing (in. (cm)) |

2.6 (7) |

|

Tine bars |

4 |

|

Number of tines |

112 |

|

Reel diameter (in. (cm)) |

12 (30.5) |

|

Pickup protection |

Multi-plate slip clutch |

Pickup Specifications - Heavy-Duty 1.8M 5-bar Pickup | |

|

Models |

Standard Silage Special; Optional Hay Special |

|

Width, inside/tine-to-tine (in. (cm)) |

71 (180) 1.8 |

|

Width, outside/flare-to-flare (in. (cm)) |

79 (202) |

|

Tine bars |

5 |

|

Number of tines |

140 |

|

Reel diameter (in. (cm)) |

12 (30.5) |

|

Pickup protection |

Multi-plate slip clutch |

Pickup Specifications - Heavy-Duty 2.0M 5-bar Pickup | |

|

Models |

- |

|

Width, inside/tine-to-tine (in. (cm)) |

- |

|

Width, outside/flare-to-flare (in. (cm)) |

- |

|

Tine spacing (in. (cm)) |

- |

|

Tine bars |

- |

|

Number of tines |

- |

|

Reel diameter (in. (cm)) |

- |

|

Pickup protection |

- |

Pickup Specifications - SuperFeed™ Heavy-Duty 2.0M Pickup | |

|

Models |

SuperFeed |

|

Width, tine-to-tine (in. (cm)) |

82 (208) |

|

Width, flare-to-flare (in. (cm)) |

90 (229) |

|

Tine spacing (in. (cm)) |

2.6 (7) |

|

Tine bars |

5 |

|

Number of tines |

160 |

|

Reel diameter (in. (cm)) |

12 (31.5) |

|

Pickup protection |

Cut-out clutch |

Pickup Specifications - CropCutter® Heavy-Duty 2.0M Pickup | |

|

Models |

CropCutter® |

|

Width, inside/tine-to-tine (in. (cm)) |

82 (208) |

|

Width, outside/flare-to-flare (in. (cm)) |

90 (229) |

|

Tine spacing (in. (cm)) |

2.6 (7) |

|

Tine bars |

5 |

|

Number of tines |

160 |

|

Reel diameter (in. (cm)) |

12 (31.5) |

|

Pickup protection |

Cut-out clutch |