Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

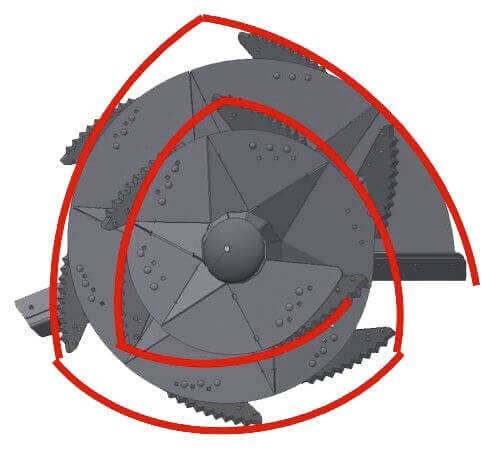

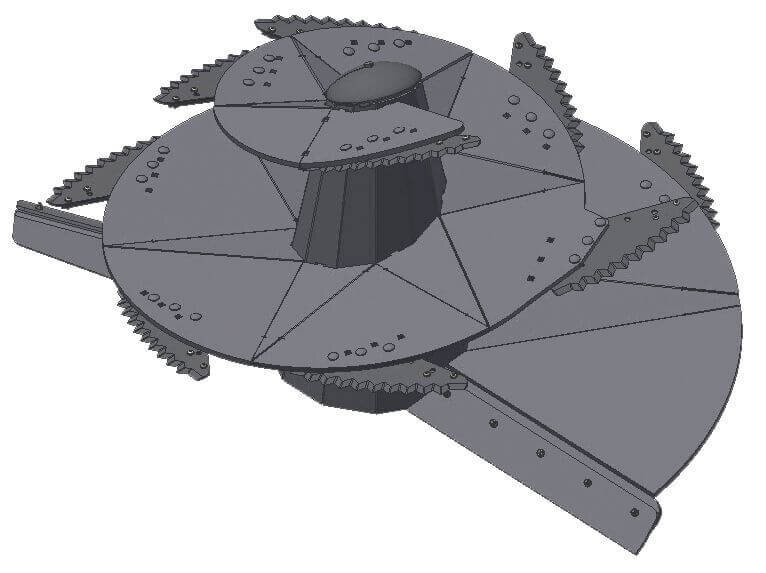

Anderson A280ST Single Auger Feed Mixer

| The Anderson A280 single auger mixers (side trap discharge) have been developed for farms where the footprint of the machines is an important factor. These mixers are compact and highly maneuvrable. The rear axle has been integrated to offer overall a very low height and perfect maneuvering. These low tubs easily fi nd their place on farms with low ceilings. |

| Capacity (no capacity extension) | 280 ft3 (7.9 m3) |

| 6 in capacity extension | 316 ft3 (9 m3) |

| 12 in capacity extension | 352 ft3 (10 m3) |

| 18 in capacity extension | 388 ft3 (11 m3) |

| Number of Auger | 1 |

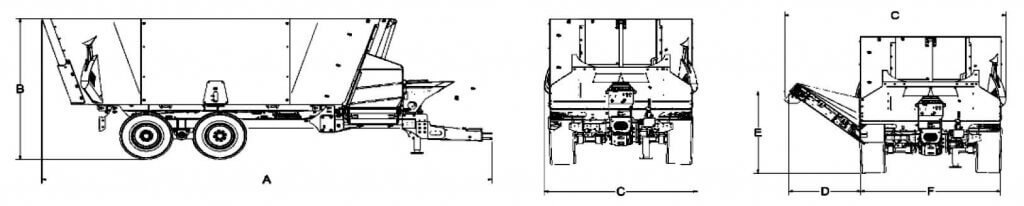

| Length (A) | 176 in (4.46 m) |

| Height (B) no extension | 98 in (2.49 m) |

| 6 in capacity extension | 104 in (2.64 m) |

| 12 in capacity extension | 110 in (2.79 m) |

| 18 in capacity extension | 116 in (2.95 m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Without incline conveyor | 90 in (2.29 m) |

| With incline conveyor (retracted) | 106 in (2.69 m) |

| Incline conveyor operating angle (degrees) | 26 @39 degrees |

| Outside width of the wheels | 86 in (2.18 m) |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 36-29in at 26º / 33-26in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 36-40in at 26º / 47-47in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 43-47in at 26º / 57-57in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 47-51in at 26º / 64-64in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 54-58in at 26º / 74-74in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 59-63in at 26º / 80-80in at 40º |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 32-36in at 26º / 41-41in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 30 in (0.77 m) |

| Name | Link |

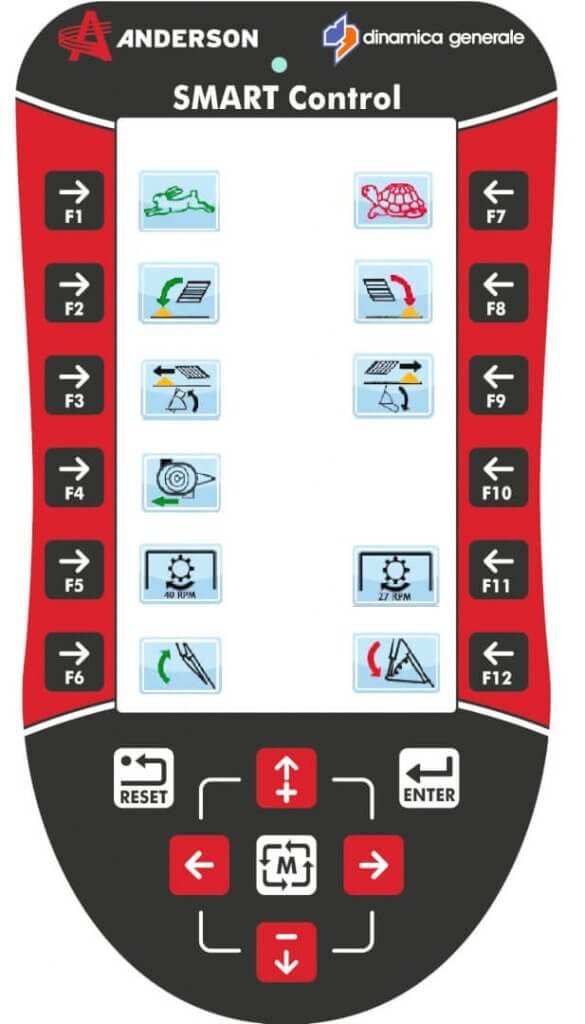

| Anderson-Manual-ENG | Download |