Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

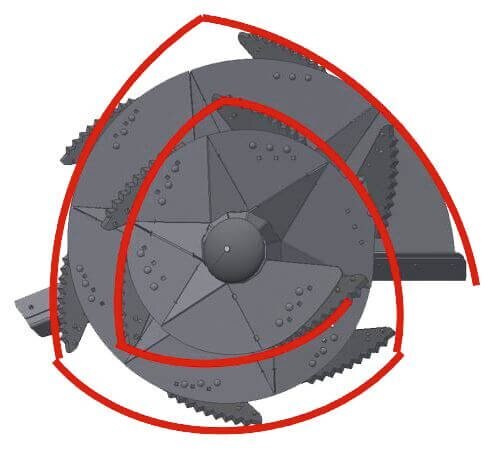

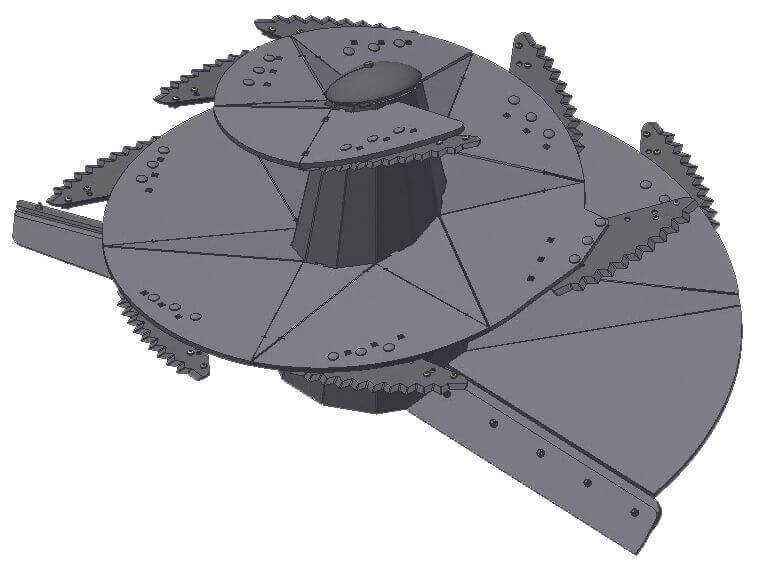

Anderson A950FD Triple Auger

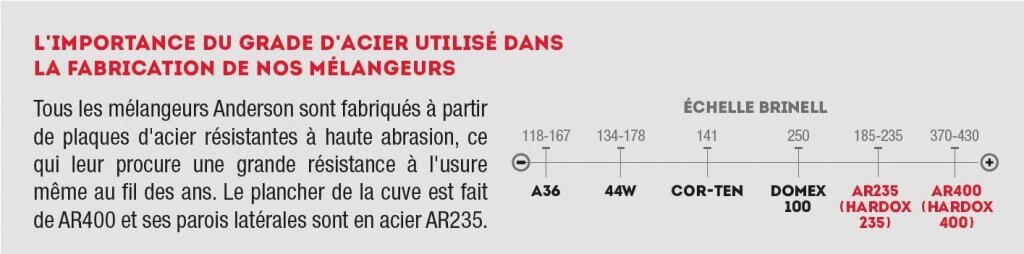

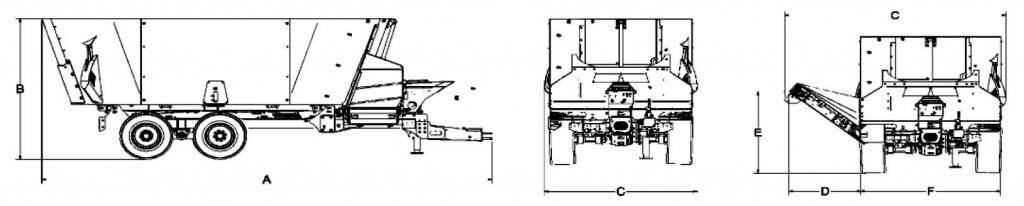

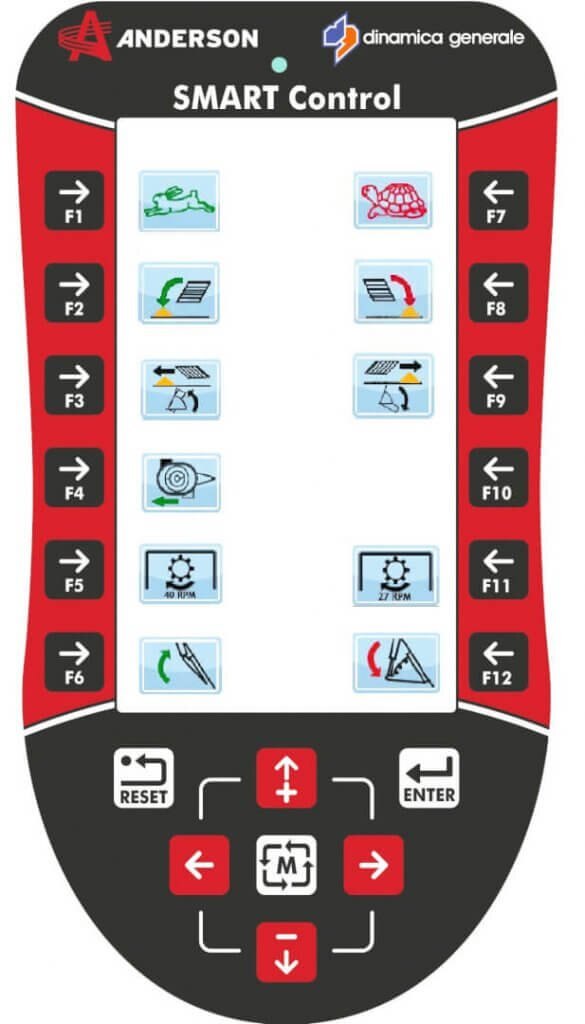

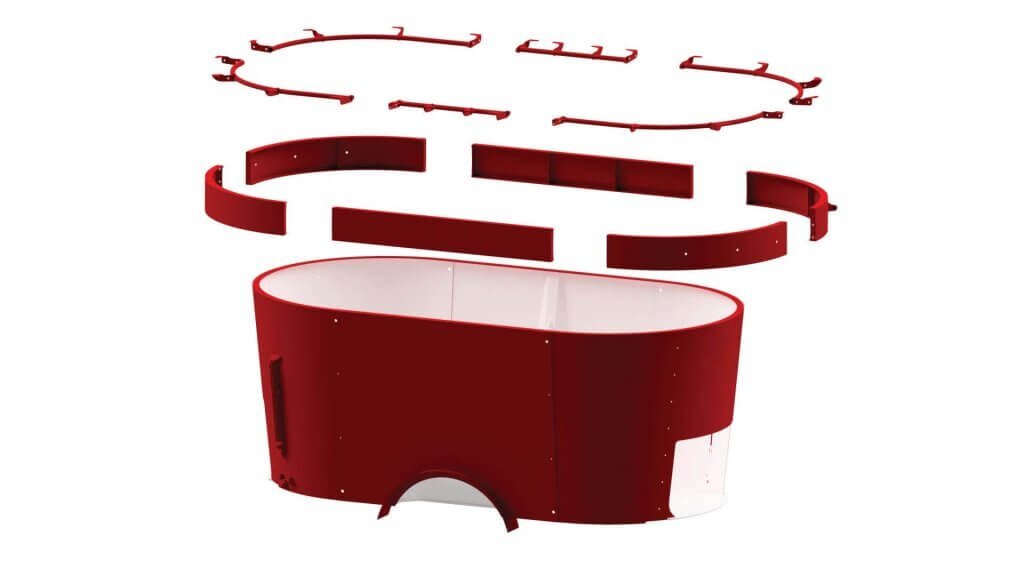

| A950FD (conveyor discharge) Anderson knows it is with high quality raw materials that we manage to achieve nutritional goals and high production. The mixing rate should be adapted to avoid any risk of over heating and grinding that could lead to diminished efficiency of the TMR. The pull type A950 triple auger mixer becomes an ideal solution with their distribution conveyor ideal for fibrous rations. The cross conveyor ensures even and prompt distribution to the left or right regardless of the prepared ration. |

| Capacity (no capacity extension) | 920 ft3 (26.1 m3) |

| 6 in capacity extension | 1017 ft3 (28.8 m3) |

| 12 in capacity extension | 1114 ft3 (31.6 m3) |

| 18 in capacity extension | 1211 ft3 (34.3 m3) |

| Number of Auger | 3 |

| Length (A) | 385 in (9.77 m) |

| Height (B) no extension | 117 in (2.97 m) |

| 6 in capacity extension | 123 in (3.12 m) |

| 12 in capacity extension | 129 in (3.28 m) |

| 18 in capacity extension | 135 in (3.43in(88888cm) m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Without incline conveyor | 101 in (2.57 m) |

| With incline conveyor (retracted) | 117 in (2.97 m) |

| Incline conveyor operating angle (degrees) | 26 @39 |

| Outside width of the wheels | 101 in (2.57 m) |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 30-28in at 26º / 28-25in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 48-50in at 26º / 57-57in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 55-57in at 26º / 68-68in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 59-61in at 26º / 74-74in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 66-68in at 26º / 84-84in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 70-72in at 26º / 90-90in at 40º |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 44-46in at 26º / 51-51in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 35 in (0.88 m) |