Anderson A520FD Twin Auger

-

ID # 35001818

- Back ID:35001818

- Book a Demo

- Get Directions

Overview

Overview

Specifications

capacity

dimensions

features and options

resource

Sales People

Contact Information

Location

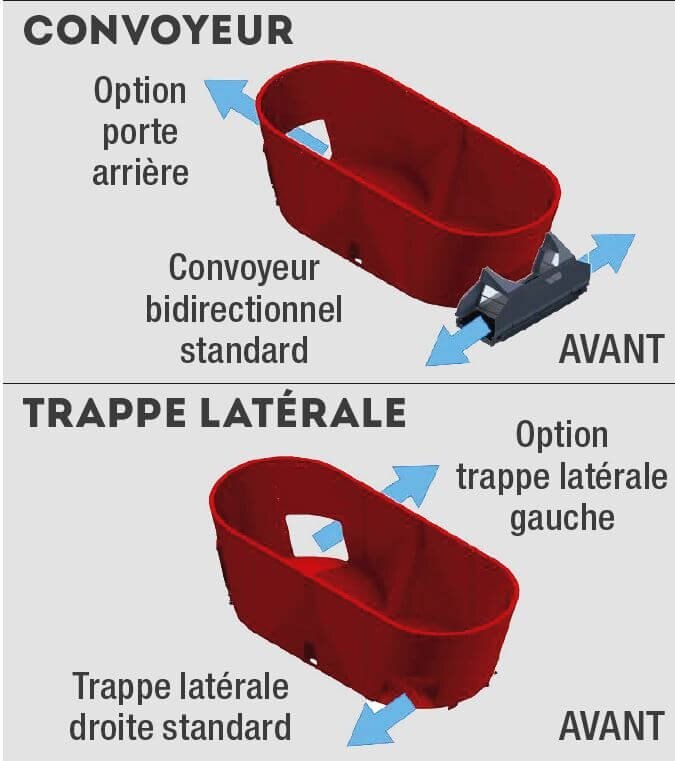

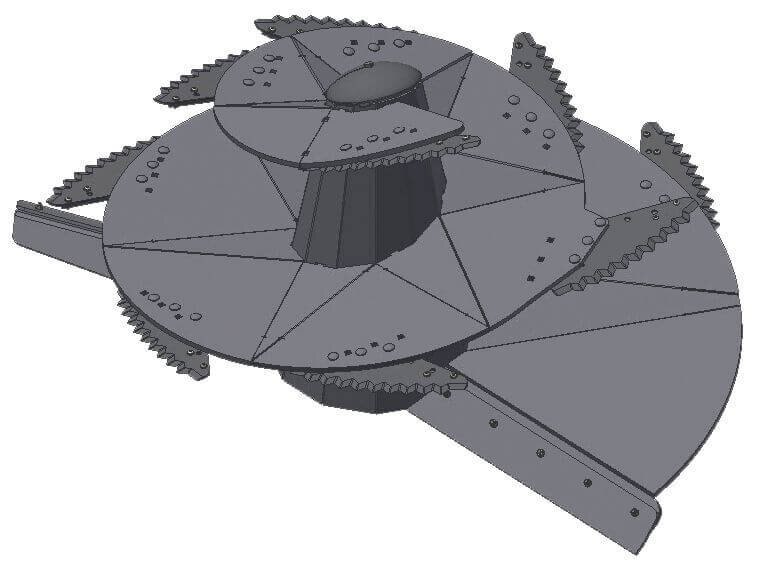

| The Anderson pull type A520 twin auger mixer (conveyor discharge) has the ability to mix the widest variety of ingredients. Process large amount of hay, even complete square and round bales of baleage. Available with several discharge options. Whether your rations are designed to increase milk production of dairy cows or minimize variation in feed for each group you feed, vertical mixer will help optimize the dry matter and nutrient intake of your herd. |

Model

A520FD Twin Auger

Category Name

Agriculture

Year

2024

Sale Type

New

Manufacturer

Anderson

Quantity

0

Manufacturer Qty

0

Load Cell

3

Scale System

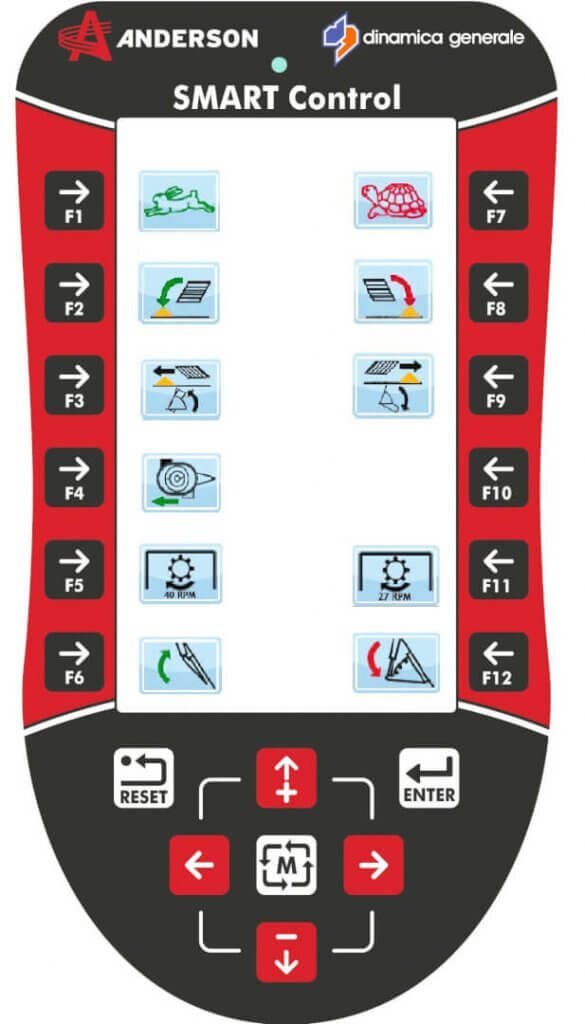

DG500 (standard)

2 Speed Gear Box

Optional

Driveline Security

Shear bolt

Hydraulic Pressure

160-200 bar (2300-2900 psi)

Utility Load Capacity

15 080 lb (6839 kg)

Auger RPM – Low Speed

27 RPM

Standard Knives Per Auger

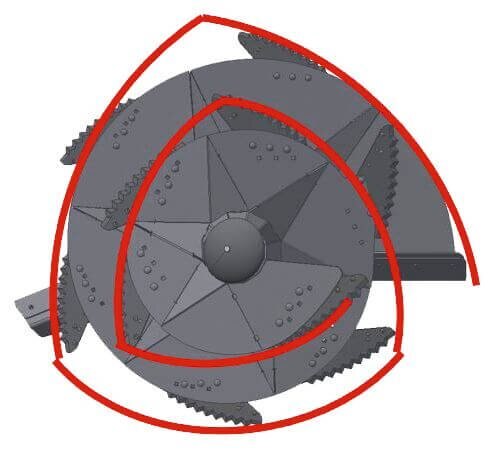

6 / 10 optional

2 Speed Gear Box And Ratio

C3A-R, 1;1,5 54in(888cm)0 RPM C3A-R, 1,8;2,7 1000 RPM

Auger RPM – Standard High Speed

41 RPM

PTO Shaft - Standard Specification

540 RPM -1’’ 3/8 Z6

Minimum PTO HP Requirement - Low Speed

80

Minimum PTO HP Requirement - High Speed

120

Machine Weight (empty) - STD Configuration

13 100 lb (59in(150cm)41 kg)

Floor Thickness (AR235 Grade Or Equivalent)

5/8 in

Flighting Thickness (AR235 Grade Or Equivalent)

5/8 in

Sidewall Thickness (AR235 Grade Or Equivalent) 1/4 In

1/4 in

Standard Planetary Model And Ratio Configuration 1603 @25,89

1603 @25,89

Capacity

| Capacity (no capacity extension) | 520 ft3 (14,7 m3) |

| 6 in capacity extension | 574 ft3 (16,3 m3) |

| 12 in capacity extension | 628 ft3 (17,8 m3) |

| 18 in capacity extension | 682 ft3 (19,3 m3) |

| Number of Auger | 2 |

Dimensions

| Length (A) | 270 in (6.86 m) |

| Height (B) no extension | 102 in (2.59in(150cm) m) |

| 6 in capacity extension | 108 in (2.74 m) |

| 12 in capacity extension | 114 in (2.9 m) |

| 18 in capacity extension | 120 in (3.05 m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Without incline conveyor | 101 in (2.57 m) |

| With incline conveyor (retracted) | 117 in (2.97 m) |

| Incline conveyor operating angle (degrees) | 26 @39 degrees |

| Outside width of the wheels | 99 in (2.51 m) |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 30-28in at 26º / 28-25in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 37-39in at 26º / 46-46in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 44-46in at 26º / 57-57in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 48-50in at 26º / 63-63in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 55-57in at 26º / 73-73in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 59-61in at 26º / 80-80in at 40º |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 33-35in at 26º / 40-40in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 24 in (0.61 m) |

Resource

| Name | Link |

| Anderson-brochure-ENG | Download |

Model

A520FD Twin Auger

Category Name

Agriculture

Year

2024

Sale Type

New

Manufacturer

Anderson

Quantity

0

Manufacturer Qty

0

Load Cell

3

Scale System

DG500 (standard)