Anderson A1230FD Triple Auger

-

ID # 35001825

- Back ID:35001825

- Book a Demo

- Get Directions

Overview

Overview

Specifications

capacity

dimensions

features and options

resource

Videos

Sales People

Contact Information

Location

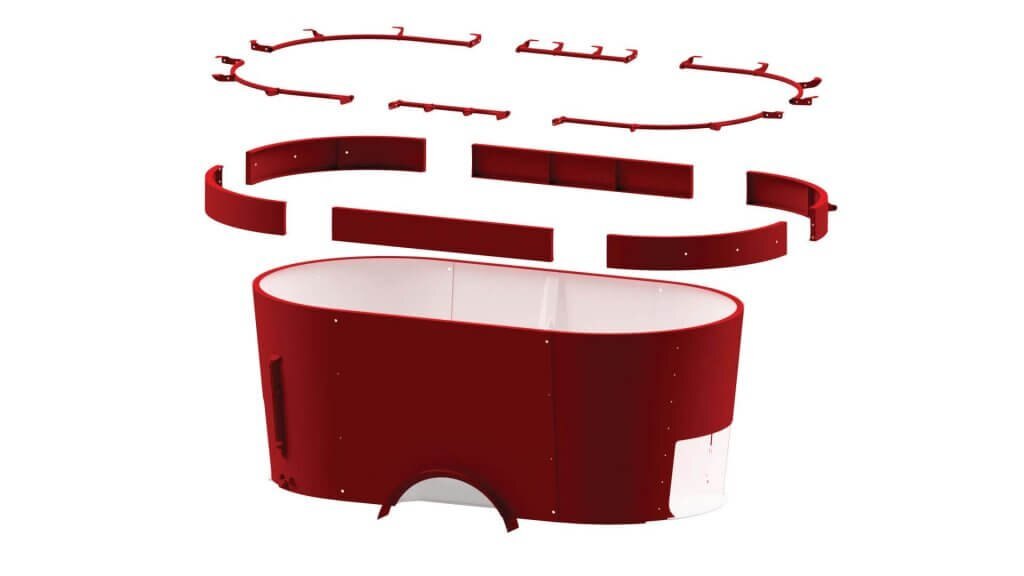

| The pull type A1230 triple auger mixer (conveyor discharge) becomeS a perfect solution with their distribution conveyor ideal for fibrous rations. The cross conveyor ensures even and prompt distribution to the left or right regardless of the prepared ration. Anderson knows it is with high quality raw materials that we manage to achieve nutritional goals and high production. The mixing rate should be adapted to avoid any risk of overheating and grinding that could lead to diminished efficiency of the TMR. |

Model

A1230FD Triple Auger

Category Name

Agriculture

Year

2024

Sale Type

New

Manufacturer

Anderson

Quantity

0

Manufacturer Qty

0

Load Cell

6

Scale System

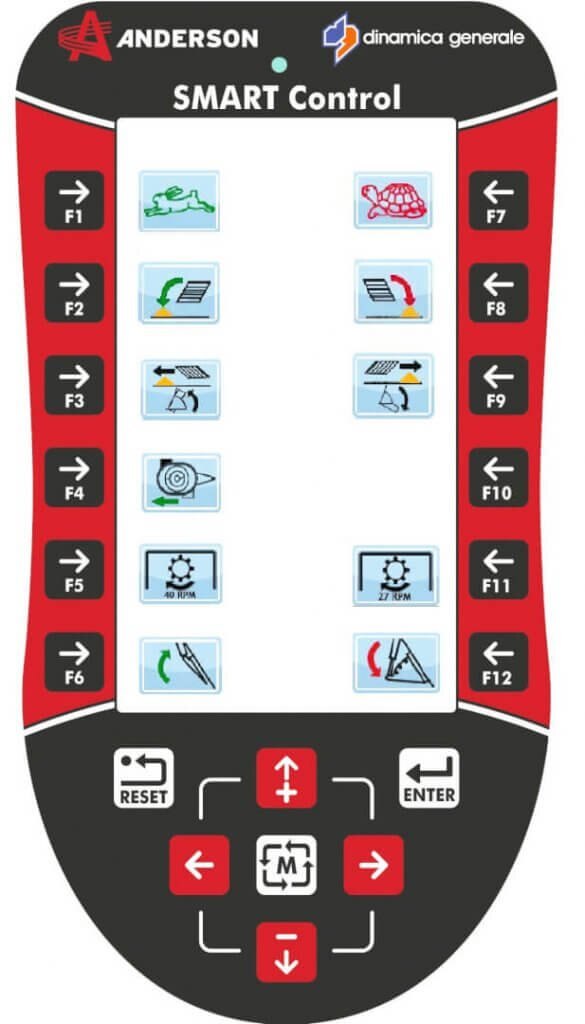

DG500 (standard)

2 Speed Gear Box

Optional

Driveline Security

Shear clutch

Hydraulic Pressure

160-200 bar (2300-2900 psi)

Utility Load Capacity

35 670 lb (16177 kg)

Auger RPM – Low Speed

18 RPM / 10 RPM

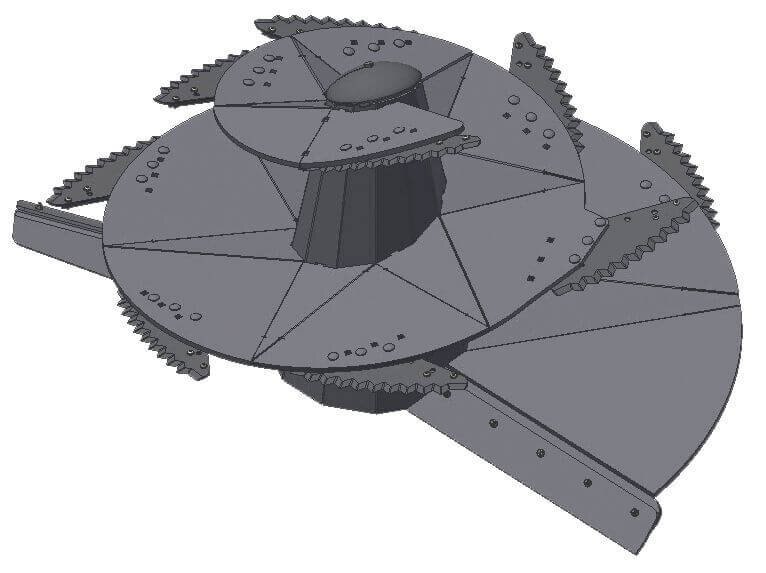

Standard Knives Per Auger

8 / 12 optional

2 Speed Gear Box And Ratio

A613R 2spd, A614R, 1;1.8;3.2@3spd

Auger RPM – Standard High Speed

33 RPM

PTO Shaft - Standard Specification

1000 RPM 1" 3/4 Z20

Minimum PTO HP Requirement - Low Speed

145

Minimum PTO HP Requirement - High Speed

210

Machine Weight (empty) - STD Configuration

28 991 lb (13148 kg)

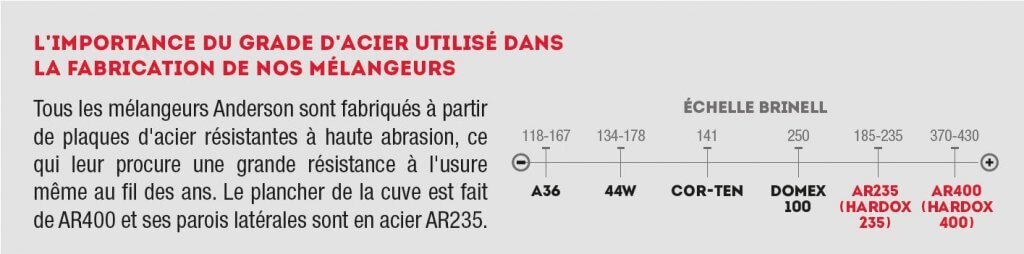

Floor Thickness (AR235 Grade Or Equivalent)

3/4 in

Flighting Thickness (AR235 Grade Or Equivalent)

5/8 in

Standard Planetary Model And Ratio Configuration

3002 @30.24

Sidewall Thickness (AR235 Grade Or Equivalent) 1/4 In

1/4 in

Capacity

| Capacity (no capacity extension) | 1230 ft3 (34.9 m3) |

| 6 in capacity extension | 1344 ft3 (38.1 m3) |

| 12 in capacity extension | 1458 ft3 (41.3 m3) |

| 18 in capacity extension | 1572 ft3 (44.5 m3) |

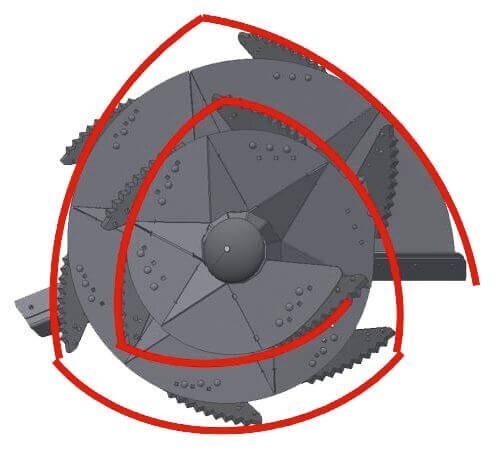

| Number of Auger | 3 |

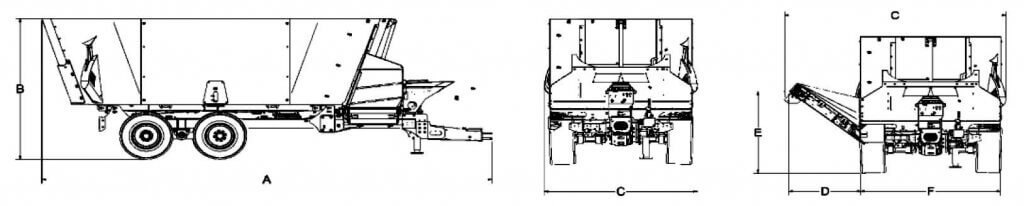

Dimensions

| Length (A) | 43in(88888cm)0 in (10.91 m) |

| Height (B) no extension | 117 in (2.97 m) |

| 6 in capacity extension | 123 in (3.12 m) |

| 12 in capacity extension | 129 in (3.28 m) |

| 18 in capacity extension | 135 in (3.43in(88888cm) m) |

| Hay retention ring (additionnal height) | 0 in / 3,5 in |

| Without incline conveyor | 112 in (2.84 m) |

| With incline conveyor (retracted) | 124 in (3.15 m) |

| Incline conveyor operating angle (degrees) | 26 @39 |

| Outside width of the wheels | 101 in (2.57 m) |

| Incline conveyor chain / belt 3 ft at min.26 angle /max 40 | 23-21in at 26º / 21-18in at 40º |

| Incline conveyor chain / belt 4 ft at min. 26 angle /max 40 | 48-50in at 26º / 57-57in at 40º |

| Incline conveyor chain / belt 5 ft at min. 26 angle /max 40 | 55-57in at 26º / 68-68in at 40º |

| Incline conveyor chain / belt 6 ft at min. 26 angle /max 40 | 59-61in at 26º / 74-74in at 40º |

| Incline conveyor chain / belt 7 ft at min. 26 angle /max 40 | 66-68in at 26º / 84-84in at 40º |

| Incline conveyor chain / belt 8 ft at min. 26 angle /max 40 | 70-72in at 26º / 90-90in at 40º |

| Incline conveyor chain / belt 3 ft at min. 26 angle /max 40 | 44-46in at 26º / 51-51in at 40º |

| Floor ST (E1) / Conveyor FD (E2) to ground | 35 in (0.88 m) |

Resource

| Name | Link |

| Anderson-brochure-ENG | Download |

Model

A1230FD Triple Auger

Category Name

Agriculture

Year

2024

Sale Type

New

Manufacturer

Anderson

Quantity

0

Manufacturer Qty

0

Load Cell

6

Scale System

DG500 (standard)