Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland PowerStar™ Series - PowerStar™ 110

|

GROSS ENGINE HORSEPOWER 107 PTO HORSEPOWER 93 | |

FIVE STARS OF UTILITYFive PowerStar™ models pack power to effortlessly tackle your jobs. Along with efficient engines and a 12x12 transmission with a power shuttle, you’ll choose between a 2WD or 4WD front axle and an ergonomic cab or ROPS platform. Get the perfect pairing with a factory-installed LU Series loader. | |

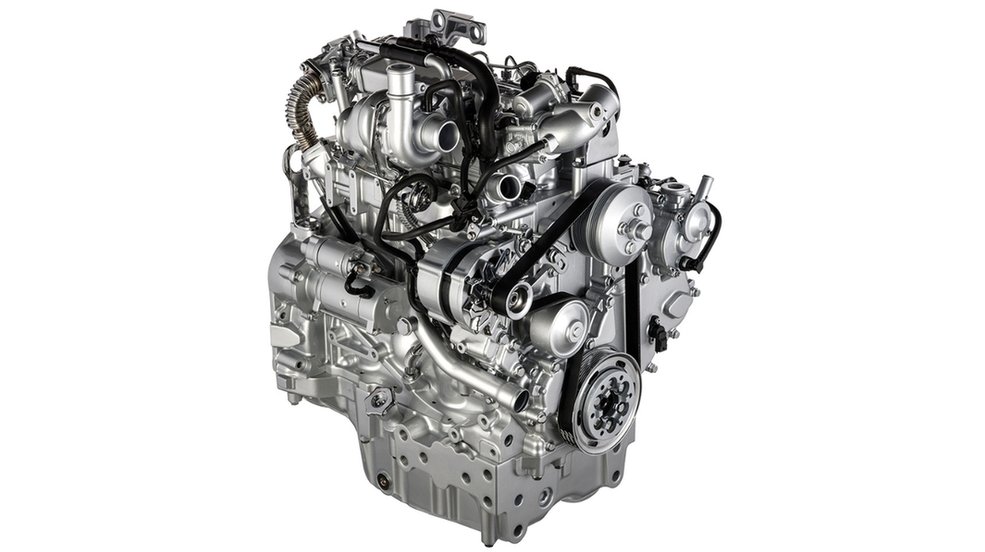

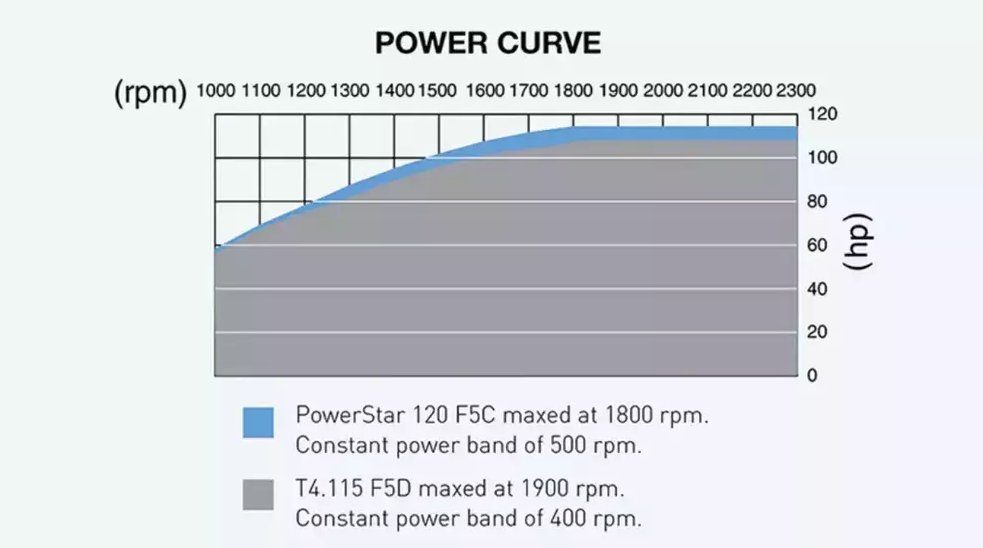

PUTTING THE POWER IN POWERSTARPower is important for a utility tractor and the PowerStar™ Series delivers, just as its name says. All models feature a 4-cylinder Tier 4B FPT engine. Unlike some competitors, no diesel particulate filter (DPF) is used, and no regeneration is required. | |

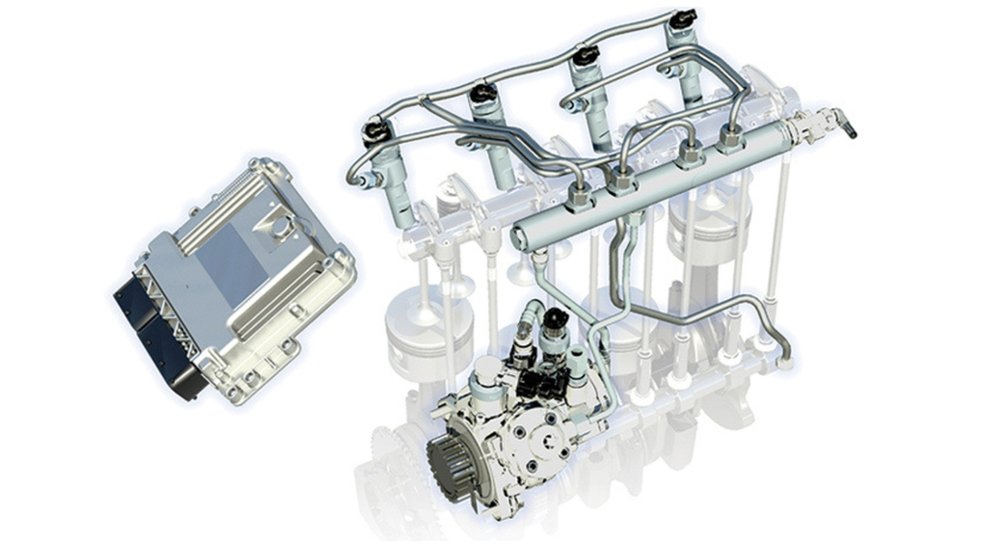

GREEN BELONGS IN YOUR POCKETCommon rail fuel injection enhances combustion and reduces fuel consumption. These engines also provide more power, torque, and efficiency compared to previous Tier 4A engines and come with an industry-leading 600-hour service interval for less downtime. | |

OUR VISION. YOUR VIEW.Inside the VisionView™ cab, the high-visibility panel pairs with the sloped hood and curved loader arms to let you see more of your work. Frequently-used controls are strategically placed on the Command Arc console and a powerful heating and cooling system, tilt steering column, and instructor seat further ensure productivity. |

THE VISIONVIEW™ CAB: OUR VISION. YOUR VIEW.Virtual-reality design and input from operators drove the design of the VisionView cab. Our goal was to maximize visibility from every angle and place controls in practical locations to allow you to operate a loader more safely and comfortably. The result is easy to see. Two wide-opening doors guarantee easy entry. The flat floor and suspended pedals enhance comfort. The instrument cluster tilts with the steering column using a simple foot pedal for adjustment. A hinged rear window opens completely with gas struts, while a lower viewing window offers exceptional visibility of rear components and assistance when attaching an implement. Just sit back, relax, and enjoy the panoramic view. | |

CONVENIENCE WHERE YOU NEED IT MOST

| |

SEAT OF POWER

| |

DUAL-ZONE COMFORT

| |

VISIBILITY ON HIGH

| |

PAIRED FOR TECHNOLOGY

|

PUTTING THE POWER IN POWERSTAR™Power is important for a utility tractor and the PowerStar Series delivers—just as its name says. All models feature a 207-cubic-inch, four-cylinder F5C engine built by FPT. To deliver more power and torque to handle your daily chores and fieldwork with ease while simultaneously reducing your fuel bills and emissions, these engines use common rail fuel injection with four valves per cylinder. All models meet stringent Tier 4B Final emissions requirements without the need for regeneration or a diesel particulate filter (DPF) and feature an industry-leading 600-hour service interval. | |

A GREENER SOLUTION THAT KEEPS GREEN IN YOUR POCKET

| |

COMMON RAIL IS COMMON SENSE

| |

EXCEPTIONAL FUEL ECONOMY

| |

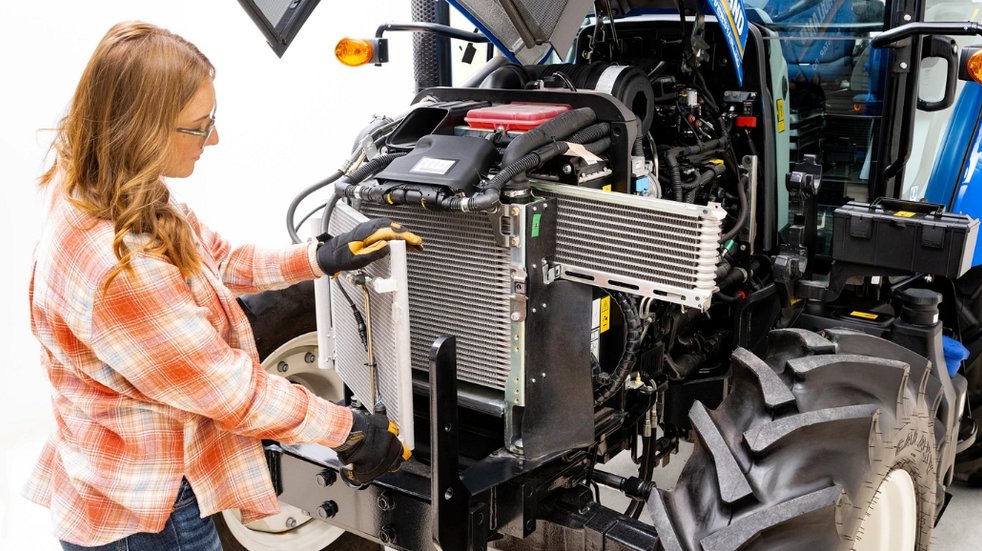

EASY SERVICING

|

FIND THE RIGHT SPEED WITH TRACTOR-TAILORED GEARINGYou’ll find the ideal speed with the gears you need on the standard 12x12 transmission, which features four synchronized gears in three ranges. The power shuttle is conveniently located on the left side of the steering column—perfect for loader work where direction changes are frequent. | |

COLUMN-MOUNTED SHUTTLE

| |

SPEED WHEN YOU NEED IT

| |

INTUITIVE SHIFTING

| |

CREEP THROUGH FIELDS

|

HEFTY HITCH AND HYDRAULICS INCREASE UTILITYNew Holland knows the ideal 3-point and hydraulic capacities you need on a utility tractor. That’s why you’ll find hefty 3-point hitch and impressive hydraulic capacity coupled to intuitive controls to ensure you accomplish all your tasks with power, ease, and comfort. | |

IMPRESSIVE 3-POINT HITCH LIFT CAPACITY

| |

CONVENIENT MECHANICAL DRAFT CONTROLS

| |

THE PUSH AND PULL OF A BUTTON

| |

STANDARD HYDRAULICS

| |

A STROKE OF CONVENIENCE

|

|

Make |

FPT F5C |

|

Type |

4-cylinder diesel |

|

Displacement (cu. in. (L)) |

207 (3.4) |

|

Gross engine horsepower |

107 |

|

PTO horsepower |

93 |

|

Rated Engine Speed (rpm) |

2,300 |

|

Aspiration |

Turbocharged / aftercooled |

|

Emissions |

Tier 4B ECOBlue™ Compact HI-eSCR + Light CEGR |

|

Service Interval (hours) |

600 |

|

12x12 Power Shuttle |

Standard |

|

20x20 Power Shuttle with Creeper |

Optional |

|

Top Speed – 4WD Front Axle (mph (kph)) |

27 (43) |

|

Top Speed – 2WD Front Axle (mph (kph)) |

20 (30) |

|

Lift capacity @ 24 in. (610 mm) (lbs. (kg.)) |

5,620 (2549) |

|

Category |

2 |

|

2 Rear Remotes |

Standard |

|

3rd Rear Remote DIA Kit |

Optional |

|

Implement Pump Flow (gpm (Lpm)) |

16.9 (63.9) |

|

Steering Pump Flow (gpm (Lpm)) |

9.7 (37) |

|

Total Flow (gpm (Lpm)) |

26.6 (100.8) |

|

540 |

Standard |

|

540 / 1000 |

Optional |

|

Fuel Tank (gal. (L)) |

30.3 (114.7) |

|

DEF Tank (gal. (L)) |

2.8 (10.6) |

|

Cab |

Standard |

|

ROPS |

Optional |

|

Weight - Cab/4WD (lbs. (kg.)) |

8,157 (3700) |

|

Weight - Cab/2WD (lbs. (kg.)) |

7,473 (3390) |

|

Weight - ROPS/4WD (lbs. (kg.)) |

7,672 (3480) |

|

Weight - ROPS/2WD (lbs. (kg.)) |

6,988 (3170) |

|

Overall width (in. (mm)) |

75.7 (1923) |

|

Overall height - Cab roof (in. (mm)) |

102.1 (2594) |

|

Overall height - top of ROPS (in. (mm)) |

106.5 (2706) |

|

Overall length - 4WD (in. (mm)) |

160.9 (4086) |

|

Overall length - 2WD (in. (mm)) |

163.1 (4144) |

|

Front weights length (in. (mm)) |

10.3 (262) |

|

Wheelbase 4WD (in. (mm)) |

89.9 (2285) |

|

Wheelbase 2WD (in. (mm)) |

92.2 (2343) |