Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland WORKMASTER™ Utility 50 – 70 Series - WORKMASTER™ 50 2WD

|

GROSS ENGINE POWER (HP (KW)) 53 (39.5) PTO HORSEPOWER (HP (KW)) 45 (34) | |

TOUGH AND RELIABLERugged construction and simple drivelines help make WORKMASTER™ tractors the dependable, economical choice. | |

CLEAN AND FUEL-EFFICIENTTurbocharged, direct injected, common rail engines save fuel and meet strict Tier 4B final emissions requirements with a system that’s completely automatic. | |

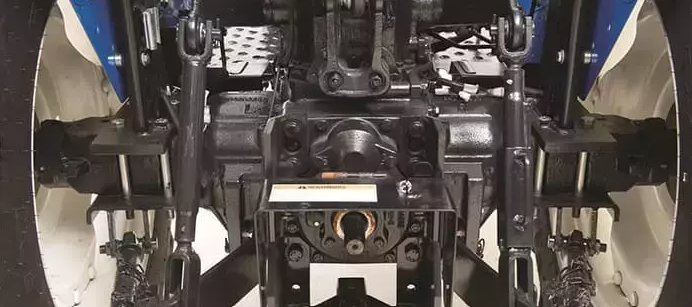

2WD OR 4WDFor added grip and performance in slippery and challenging conditions, upgrade to the 4WD front axle with limited slip, front differential lock. | |

THREE HEAVY-DUTY MODELSWORKMASTER models at 53, 60 and 70 horsepower serve as ideal mid-size tractors for municipalities, landscapers, grounds crews, farmers and ag lifestylers. |

THE POWER BEHIND A JOB WELL DONEAmple power and a durable design make routine chores and ambitious projects easy. Three WORKMASTER™ models let you choose between 53, 60 or 70 engine horsepower, that offer a quiet start-up and smooth, fuel-efficient operation. Tier IV emission compliant engines protect the environment and give you the flexibility to run on B7 biodiesel blends. | |

AUTOMATIC EMISSIONS SYSTEM

| |

SMOOTH AND RESPONSIVE

|

EXACTLY WHAT YOU NEEDYou'll find the speeds you need to match any task in the new WORKMASTER™ tractors. Just like an automobile, gears are arranged in a simple pattern, and the WORKMASTER 50, 60 and 70 offer a convenient 8 x 8 synchronized shuttle that lets you easily flip from forward to reverse and back again. With operation this smooth, you'll cruise through chores and be ready to tackle your next big project. | |

MORE SPEEDS

| |

EASY MANEUVERS

|

ACCOMPLISH MORE WITH HEAVIER IMPLEMENTSThe 3,500-pounds of three-point hitch lift capacity means you can make the most of heavy implements. When more is required you can option up with the auxiliary lift cylinder that increases capacity to 4,000 pounds. | |

CUSTOM LOADER

| |

AVAILABLE FWD FRONT AXLE

| |

HIGH-STRENGTH REAR AXLE

| |

3-POINT HITCH

| |

TANDEM HYDRAULICSGo ahead and multitask. The open-center hydraulic system utilizes dual hydraulic pumps so you get all the power you need for steering, rear remote valves, three-point hitch and loader work. | |

540 OR 540/540e PTO

|

|

Make |

FPT - R753 |

|

No. of Cylinders / Aspiration |

3, Turbo |

|

Displacement (cu.in (L)) |

136 (2.2) |

|

Gross engine power (hp (kW)) |

53 (39.5) |

|

PTO horsepower (hp (kW)) |

45 (34) |

|

Rated speed (rpm) |

2600 |

|

Fuel type |

Direct Injection /Common Rail |

|

Air Filter |

2 - stage |

|

Standards |

4B final |

|

Fuel tank capacity (gal. (L)) |

17.2 (65) |

|

Traction clutch |

Dry, 11" (279.4 mm) diameter, organic plate |

|

8x8 Synchro Shuttle |

8Fx8R Synchronized Shuttle with synchronized gears and non-synchronized ranges |

|

Standard Rear Tire |

13.6-28 (R1) |

|

Optional Rear Tire |

18.4-24 (R4), FWD |

|

Service brakes |

Mechanical multi-plate wet disc |

|

Parking brake |

Engage hard-lever, press brake pedals to lock service brakes |

|

Rear differential lock |

Mechanical foot pedal engagement |

|

FWD clutch engagement |

Mechanical, FWD |

|

System type |

Open center, fixed displacement gear pump |

|

Implement pump capacity (gpm (Lpm)) |

12 (45) |

|

Steering & services system (gpm (Lpm)) |

5.5 (21) |

|

Total maximum tractor flow (gpm (Lpm)) |

17.5 (66) |

|

Remote valves |

Open center, float detent available for #1, #2 FIO or DIA |

|

Category |

II/I |

|

Position control, draft sensing |

One lever, standard mechanical draft control |

|

OECD lift capacity @ 24 in. (609.6 mm) behind ball ends (lbs. (kg)) |

2,701 (1225) |

|

PTO type |

Independent Mechanical Engagement |

|

Rear PTO |

540 RPM Standard / 540/540E Economy optional |

|

Alternator (amps) |

75 |

|

Battery capacity (cold cranking amps) |

720 |

|

Lighting |

2 halogen headlights, 2 halogen corning worklights, flashing safety lights/turn signals |

|

Accessory power outlets |

Standard equipment, 7-pin implement outlet |

|

ROPS |

Foldable |

|

Shipping length (in. (mm)) |

129.5 (3290) |

|

Shipping width (in. (mm)) |

77.5 (1970) |

|

Shipping height (in. (mm)) |

97.6 (2479) |

|

Shipping weight (lbs. (kg)) |

4,442 (2015) |