Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland Discbine® PLUS Center-Pivot Disc Mower-Conditioners - Discbine® 316 PLUS

|

TRANSPORT WIDTH (FT. IN. (M)) 16’ 8” (5.07) CUTTING WIDTH (FT. IN. (M)) 16’ 5” (5.0) | |

CLEANER AND CLOSER CUTTINGGet the cleanest and closest cut yet with the MowMax™ II PLUS true modular cutterbar. Faster knife tip speed, a slimmer cutterbar profile, and reshaped rock guards improve cut quality while providing a 30% lower cutting height. | |

TIME-SAVING INNOVATIONSThe standard QuickMax™ knife-change system and ShockPRO™ hubs are designed to save you hassle when you’re making hay. For ultimate peace of mind, a 2-year base warranty is standard along with an additional year of MowMax™ cutterbar warranty so you can cut with even more confidence. | |

PIVOT TO GREATER PRODUCTIVITYWhether you need a nimble mower to enter tight places or big capacity for wide-open spaces, four center-pivot models, with cut widths from 10- to 16 ft. (3 to 5 m) wide, are designed and built with pride in New Holland, Pennsylvania. | |

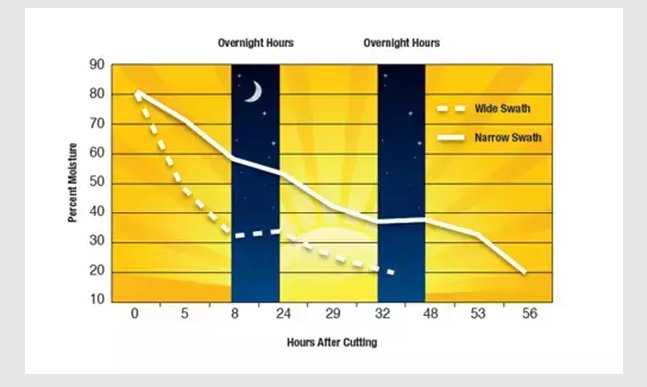

FROM WIDE SWATHS TO NARROW WINDROWSChoose between the chevron intermeshing rubber or steel rolls, or the LeaningEdge™ flail tine conditioning system. Enhanced swath control surfaces behind the conditioning system result in neater-looking swaths with improved dry down. |

FROM WIDE SWATHS TO NARROW WINDROWSFast drying requires crop to be evenly distributed over a wide swath. To help, the Discbine® PLUS Series provides enhanced swath control surfaces behind the conditioning system. | |

THE ADVANTAGES OF SPREADING CROP WIDE AND THIN

| |

BETTER CONTROL MEANS BETTER WINDROWS

| |

WEDGES AND FINS

|

|

Type |

MowMax™ II PLUS true modular cutterbar |

|

Cutting width (ft. in. (m)) |

16’ 5” (5.0) |

|

Cutting height (in. (mm)) |

0.5 – 2.6 (12 – 65) |

|

Cutting height with optional adjustable shoes (in. (mm)) |

0.5 – 5.6 (12 – 143) |

|

Number of discs / knives per disc |

10 / 2 |

|

Maximum disc speed @ 1,000 rpm PTO |

2250 |

|

Hydraulic tilt/cutting height control |

Standard |

|

Tilt angle (degrees) |

-2° to -10° |

|

Header flotation |

Vertical & lateral, adjustable springs |

|

ShockPRO™ disc drive protection system |

Standard |

|

3-year factory cutterbar warranty |

Standard |

|

Chevron intermeshing rubber rolls |

Optional |

|

Chevron intermeshing steel rolls |

Optional |

|

Length (in. (mm)) |

125 (3175) |

|

Diameter (in. (mm)) |

10.4 (264) |

|

Drive method |

Belt-driven, enclosed gearbox |

|

Speed (rpm) |

750 or 640 |

|

Conditioner roll tension adjustment |

Standard |

|

Conditioner gap adjustment |

Standard |

|

Compatibility |

Optional |

|

Number of tapered flail tines |

— |

|

Length (in. (mm)) |

— |

|

Diameter (in. (mm)) |

— |

|

Drive method |

— |

|

Speed (rpm) |

— |

|

Conditioner gap adjustment |

— |

|

Swath width (ft. (m)) |

10 (3) |

|

Windrow width (ft. (m)) |

3 – 8 (.91 – 2.4) |

|

540 rpm, 6-spline 1.625 in. (41.3 mm) input speed |

— |

|

1,000 rpm, 21-spline 1.625 in. (41.3 mm) input speed |

Standard |

|

Slip and overrunning clutch protection |

Standard |

|

Drawbar swivel |

Standard |

|

Drawbar category |

ASAE Category II or III |

|

2-point semi-mount swivel |

Optional |

|

3-point hitch category |

ASAE Category II, III-N, or III |

|

Minimum PTO horsepower |

100 |

|

Hydraulic requirement – rubber rolls |

1 double acting, 1 single acting |

|

Hydraulic requirement – steel rolls |

1 double acting, 1 single acting |

|

Hydraulic requirement – flails |

— |

|

Electrical |

7-pin connector for transport lights |

|

Transport width (ft. in. (m)) |

16’ 8” (5.07) |

|

Operating weight – rubber rolls (lbs. (kg)) |

6980 (3166) |

|

Operating weight – steel rolls (lbs. (kg)) |

7080 (3211) |

|

Operating weight – flails (lbs. (kg)) |

— |