Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland Windrower Headers - Durabine™ 416 PLUS

|

CUTTING WIDTH (FT. IN. (M)) 16' 3" (4.95) NUMBER OF DISCS 10 | |

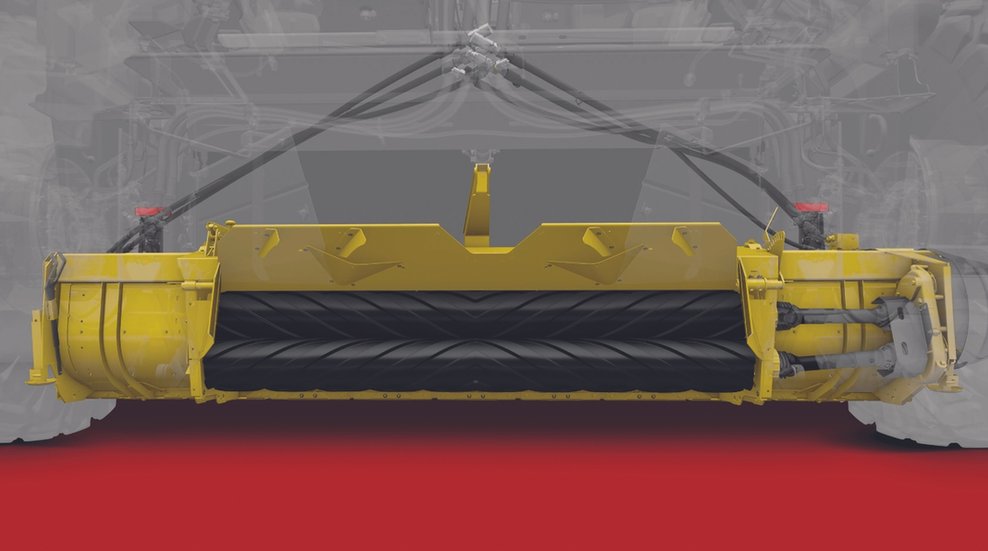

REDESIGNED FOR FASTER SPEEDDurabine™ PLUS Series disc headers take advantage of faster speeds on Speedrower® PLUS windrowers without compromising cutting and conditioning quality. | |

CLEAN & CLOSE CUTTINGThe MowMax™ II PLUS true modular cutterbar found on Durabine PLUS heads provides an even cleaner cut with faster tip speed and a lower-profile compared to previous models. | |

LEGENDARY PERFORMANCEHaybine® HS Series sickle headers continue the legacy of impeccable cutting performance, fast drying, and time-tested reliability. | |

UNIFORM, FAST-DRYING SWATHSChoose the best conditioning system for your crops – rubber chevron rolls, steel chevron rolls, or high-contact chevron rolls. |

CLEAN AND CLOSE CUTTINGTo maximize productivity, the all-new MowMax™ II PLUS true modular cutterbar delivers a cleaner cut. Longer knives extend each module’s cutting diameter by nearly 1 inch (25.4 mm) and turn with a tip speed of 171 mph (275 kph) at 2300 rpm on the Durabine™ 413 PLUS and 195 mph (314 kph) at 2600 rpm on the Durabine 416 PLUS and 419 PLUS, which is 14 mph (22 kph) faster than the previous series (181 mph (291 kph)). For better crop-to-knife engagement, the cast rock guards were reshaped. To improve cutting in light- or late-season crops, the profile of the cutterbar was lowered by bringing the discs closer to the cutterbar with new low profile ShockPRO™ hubs. Along with the longer knives, this design is more productive in down and tangled crops as the cutting height was lowered nearly 30%, leaving less uncut crop behind. | |

3-YEAR MOWMAX™ CUTTERBAR WARRANTY

| |

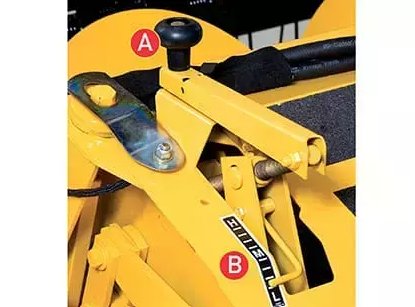

SAVE TIME WITH THE QUICKMAX™ KNIFE-CHANGE SYSTEM

| |

AVAILABLE KNIFE OPTIONS

| |

SMOOTH AND CONSISTENT FEEDING (DURABINE™ 416 PLUS & 419 PLUS)

| |

VERSATILE, MODULAR CONDITIONING SYSTEMSDiverse crop harvesting is no problem for the Durabine™ PLUS Series. You can change conditioning modules quickly to suit crops and maximize quality or remove the conditioning module entirely and outfit the header with a closure kit for wide swaths of non-conditioned hay. The large, 10+ inch (254 mm.) diameter rolls with a chevron-lug profile grip the crop and provide even flow through the rolls for uniform conditioning and fast-drying swaths or windrows. Tailor roll pressure to crop yields without tools with the turn of a hand crank that delivers consistent, thorough conditioning for all crops. All systems feature the proven torsion-bar roll-pressure system with over-center linkage that momentarily releases roll pressure, allowing slugs of crop or foreign objects to pass without plugging for non-stop mowing. | |

UNIFORM, FAST-DRYING SWATHS

| |

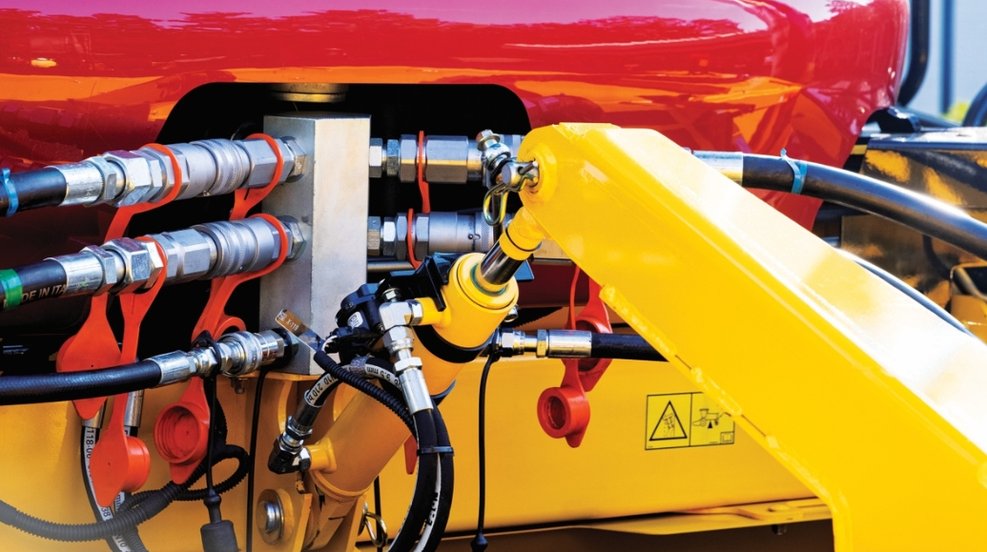

IMPRESSIVE HEADER POWER

|

PROVEN CUTTING AND CONDITIONING PERFORMANCESince 1964 when New Holland introduced the industry’s first combined mower-conditioner, the Haybine® name has been associated with impeccable cutting performance, fast drying, and time-tested reliability. Three sizes are available with cutting widths of 14’ 3” (4.34 m.), 16’ 3” (4.95 m), and 18’ 3” (5.56 m). For clean cutting performance, dual counter-stroking sickles feature a timed modular wobble drive that assures smooth cutting with minimal vibration and maintenance. Over-serrated knives slice quickly at 1800 rpm as the fully adjustable five-bat reel consistently feeds crop into the 20-inch (508 mm) auger. Fast dry down is the result of 102-inch (2591 mm) wide chevron-pattern intermeshing rubber or steel rolls that use a proven torsion-bar roll-pressure system to apply constant pressure. | |

CONSISTENT CROP FEEDINGThe fully-adjustable five-bat reel sweeps crop smoothly to the exclusive floating auger. This 20-inch auger with five-inch flighting floats up to two inches to handle heavy crops and delivers crop evenly to the conditioning rolls. | |

PROVEN CONDITIONING

|

|

Cutting width (ft. in. (m)) |

16' 3" (4.95) |

|

Overall width (ft. in. (m)) |

16' 7" (5.05) |

|

Weighting with conditioning system (lbs. (kg)) |

5114 (2319) |

|

Weight less conditioning system (lbs. (kg)) |

- |

|

Cutting width (ft. in. (m)) |

16' 3" (4.95) |

|

Cutting height range (in. (mm)) |

.5 - 3.3 (13 - 86) |

|

Cutting angle (degrees) |

0 to -10 |

|

Number of discs |

10 |

|

Maximum disc speed (rpm) |

2600 |

|

Number of reversible, swing-away knives |

20 |

|

Knife tip speed (mph (kph)) |

195 (314) |

|

Flotation |

Hydraulic adjustment from cab |

|

ShockPRO™ Disc Drive Protection System |

Standard |

|

3-Year MowMax™ Factory Cutterbar Warranty |

Standard |

|

Cutting width (ft. in. (m)) |

- |

|

Cutting height range (in. (mm)) |

- |

|

Cutting angle (degrees) |

- |

|

Type |

- |

|

Knives |

- |

|

Guards |

- |

|

Skid shoes |

- |

|

Drive type |

- |

|

Speed (spm) |

- |

|

Stroke (in. (mm)) |

- |

|

Type |

- |

|

Adjustments |

- |

|

Mechanical drive (rpm) |

- |

|

Hydraulic drive (optional) (rpm) |

- |

|

Speed adjustment (mechanical) |

- |

|

Diameter (in. (mm)) |

- |

|

Drive type |

- |

|

Tine bars |

- |

|

Bushings / bearings* (in. (mm)) |

- |

|

Auger diameter (in. (mm)) |

20 (508) |

|

Auger type |

Floating |

|

Roll types |

Chevron pattern rubber or steel or B&D's "The Crusher" rubber rolls |

|

Roll length (in. (mm)) |

102 (2591) |

|

Roll diameter (in. (mm)) |

10.16 (258) |

|

Roll speed (rpm) |

938 |

|

Roll pressure |

Hand crank |

|

Roll gap |

Adjustable stop-bolt |

|

Roll drive |

Spur gearbox and PTOs |

|

Windrow/swath width (in. (mm)) |

38 to 96 (965 to 2438) |