Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

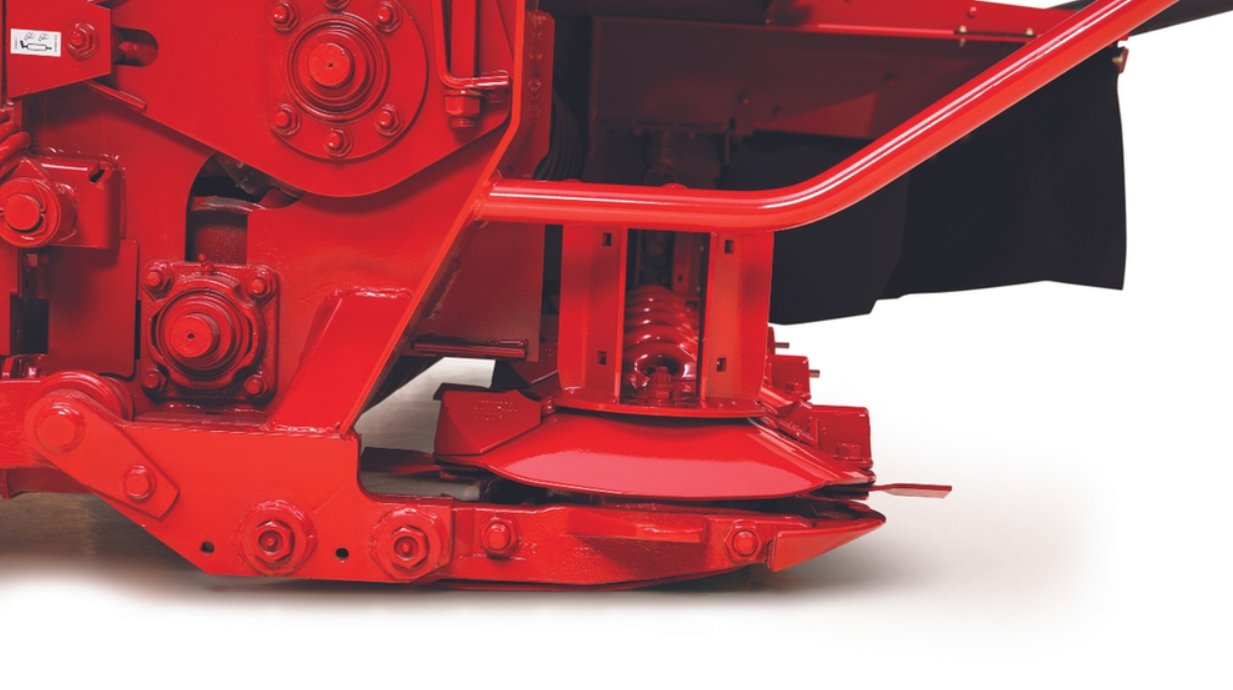

New Holland Discbine® Side-Pull Disc Mower-Conditioners - Discbine® 209

|

CUTTING WIDTH (FT. IN. (M)) 9’ 2” (2.8) NUMBER OF DISCS 7 | |

FAST, SMOOTH CUTTINGThe maneuverable 9’2” (2.8 m) Discbine® 209 and the 10’4” (3.16 m) Discbine® 210 make high-quality hay with the smooth, trouble-free performance you expect from a genuine Discbine®. | |

CUT WITH EVEN MORE CONFIDENCEFor ultimate peace of mind, a 2-year base warranty is standard along with an additional year of the MowMax™ cutterbar warranty so you can cut with even more confidence. | |

STANDARD QUICKMAX™ KNIFE CHANGE SYSTEMThe QuickMax knife change system makes it easy to keep knives sharp for the close, clean cut you want and increased tonnage. | |

HIGH QUALITY AND FAST DRYDOWNChoose the best conditioning system for your crops – rubber chevron rolls, steel chevron rolls or LeaningEdge™ flail tines. |

SAVE TIME AND MOW BETTER WITH THE QUICKMAX™ KNIFE CHANGE SYSTEMWhen you use sharp knives, you get a smooth finish, add tons to your harvest and improve the cut quality of future cuttings. With the QuickMax system, a special knife tool allows you to change bent or dull knives in less time than getting out of the tractor, so you save time and crop. |

|

Cutting width (ft. in. (m)) |

9’ 2” (2.8) |

|

Cutterbar model |

MowMax™ Modular Cutterbar with ShockPRO™ hubs |

|

Number of discs |

7 |

|

Knives per disc |

2 |

|

Disc speed @ 540 rpm PTO speed (rpm) |

3000 |

|

Tilt angle (degrees) |

2° - 10° |

|

Flotation |

Up & back, adjustable springs |

|

Drive method |

PTO drive with slip & overrunning clutch to bevel gearbox to LH end of header, vertical PTO shaft to cutterbar |

|

Cutting height (in. (mm)) |

1.1-2.7 (29-68) |

|

Cutting height w/optional high-stubble shoes (in. (mm)) |

2.25-4.5 (58-115) |

|

Cutting height w/optional adjustable shoes (in. (mm)) |

2.25-4.5 (58-115) |

|

Type |

Chevron intermeshing rubber |

|

Length / Diameter (in. (mm)) |

90 (2286) / 10.4 (264) |

|

Drive method |

4 HB V-belt and enclosed gears |

|

Speed (rpm) |

647 |

|

Conditioner roll tension adjustment |

Single crank |

|

Conditioner gap adjustment |

Adjustable drawbolt stop, each end |

|

Type |

Flail rotor with 90 tapered flails |

|

Length / Diameter (in. (mm)) |

90 (2286) / 22 (560) |

|

Drive method |

4 HB v-belt |

|

Speed (rpm) |

718 standard, 1000 optional |

|

Conditioner gap adjustment |

Single crank adjustable rotor hood |

|

Swath width (ft. (m)) |

6 (1.83) |

|

Windrow width (ft. (m)) |

3-6 (0.9-1.83) |

|

Input speed (rpm) |

540 |

|

Driveline protection |

Slip clutch and overrunning clutch assembly at rear of PTO shaft |

|

Secondary driveline |

Non-CV driveline |

|

Type |

Side-pull, straight tongue |

|

Hitch type |

Drawbar with CV PTO |

|

Minimum PTO power required (hp (kW)) |

65 (49) |

|

Hydraulic circuits required |

2 |

|

Minimum relief pressure required (psi (bar)) |

1500 (103) |

|

Drawbar |

ASAE Category II |

|

Swivel Hitch - Drawbar |

— |

|

Swivel Hitch - 2-Point |

— |

|

Electrical |

7-pin electrical connector for transport lights |

|

Tubeless ag rib implement tires |

9.5L x 14L 6PR |

|

Max road speed (mph (kph)) |

20 (32) |

|

Width, transport (ft. in. (m)) |

9’ 11” (3.02) |

|

Width , operating (ft. in. (m)) |

14’ 10” (4.52) |

|

Length, transport (ft. in. (m)) |

Flail Tine: 18’ 1’’ (5.50)*** or Roll: 17’ 7’’ (5.23)*** |

|

Length, operating (ft. in. (m)) |

Flail Tine: 17’ 8’’ (5.4)*** or Roll: 17’ 2’’ (5.23)*** |

|

Height (ft. in. (m)) |

Transport: 5’ 8” (1.73) / Operating: 4’ 5” (1.35) |

|

Ground clearance with head fully raised (in. (mm)) |

17 (4.32) |

|

Operating weight (lbs. (kg)) |

Flail Tine: 3690 (1674)*** / Roll: 3740 (1697)*** |