Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland Stackcruiser® Self-Propelled Bale Wagons - Stackcruiser® 102

|

BALE SIZE 14”X18” (36 X 46 CM) OR 16”X18” (41X 46 CM) (ADD MIL-STAK® CLAMP FOR 3’X3’ (91 X 91 CM) OR 3’X4’ (91 X 122 CM)) LENGTH 30 FT., 11 IN. (9.4 M) | |

SMALL BALES, LARGE BALES OR BOTHOnly New Holland bale wagons offer the versatility to handle such a wide variety of bale sizes — small square bales, large square bales, or both! | |

MORE POWER AND TRACTIONIncreased hydraulic capacity, a 190-horsepower engine and rear differential lock mean every Stackcruiser® bale wagon delivers more efficiency and productivity in the field. | |

MORE CONVENIENCEThe Stack Command™ II system provides a wide selection of pre-programmed and customizable bale stacking patterns to take the stress out of your day. | |

A LONG AND PROUD HERITAGENew Holland provides more than 60 years of leadership in automated bale handling. Today's Stackcruiser® models provide more power and efficiency than ever before. |

SMOOTH, EFFICIENT POWERAt 190 horsepower, today’s Stackcruiser® self propelled bale retrievers deliver more power and efficiency than ever before—just what you need to handle long days of loading, hauling and stacking. | |

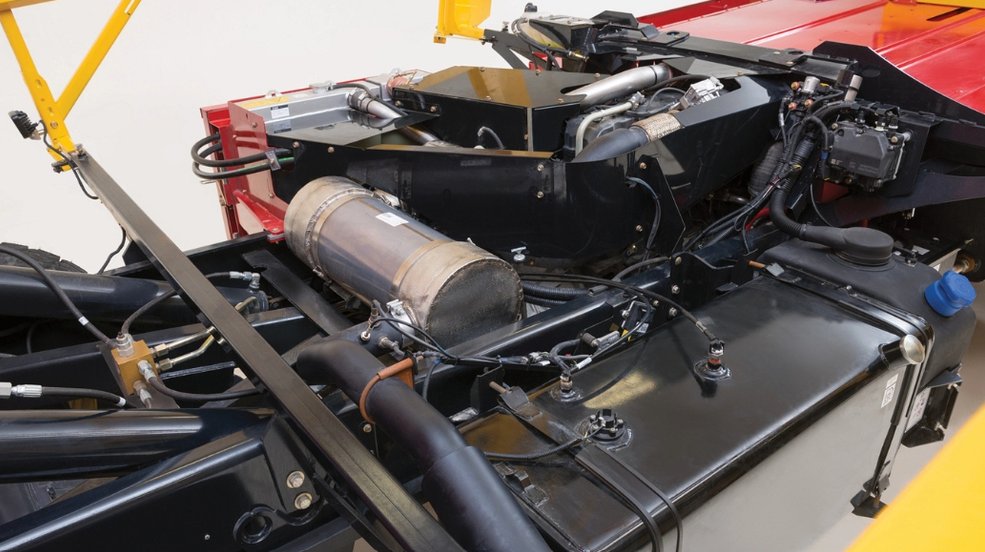

ECOBLUE™ TECHNOLOGY

| |

FIVE SPEEDS FOR EASY LOADING AND TRANSPORTIn the field or on the road, the Stackcruiser® five-speed automatic transmission with lock-up torque converter provides excellent speed matching ability. First gear provides a slower ground speed for increased productivity in high-density crops, while the overdrive in fifth gear allows for fast 50-mph road transport. | |

THE EFFICIENCY OF MULTIPLE PUMPSTwo hydraulic systems with three pumps provide plenty of flow where it’s needed when loading bales in the field. The result—faster cycle times, particularly when working with large square bales and the Mil-Stak® clamp. A 7.0-gpm (gallons per minute) gear pump provides flow for the power steering, brake booster and the park brake. An 18.0-gpm gear pump supplies the hydraulic motors that operate the bale loader and cross conveyor. A 31.5-gpm piston pump provides flow for the closed-center, load-sensing hydraulic system that provides flow to the cylinders that require higher flow. | |

ADJUST BALE DELIVERY SPEEDFirst table and/or auxiliary first table flow control valves allow you to adjust bale delivery speed if you deal with bales that vary greatly in weight. | |

HIGH PRODUCTIVITY EVEN IN DUSTY CONDITIONSA cooling fan reverser automatically reverses the fan after each load to help blow dirt out of the radiator and intercooler and remove chaff from the radiator screen. | |

EASY SERVICING

| |

HEAVY-DUTY FRONT AXLE EXPANDS VERSATILITY

| |

LOCKING REAR DIFFERENTIAL FOR TRACTION WHEN YOU NEED IT

|

PRECISION AND EASEYou stack bales in comfort and with precise control from the quiet, iso-mounted Stackcruiser® cab. Sit in the air-ride, adjustable swivel seat featuring lots of legroom thanks to the design of the tilt steering column and right-hand control console. | |

OUTSTANDING VISIBILITY, DAY OR NIGHT

| |

CONVENIENT, SINGLE-HANDED CONTROL

| |

STAY COOL ON THE WARMEST DAYSComplete climate control further enhances your comfort with multiple air vents and simple adjustments to control the flow of air conditioning and optional heat to suit your liking. The HVAC condenser is now separate from the coolers for more effective operation and eliminating cab warm up when unloading stacked bales. | |

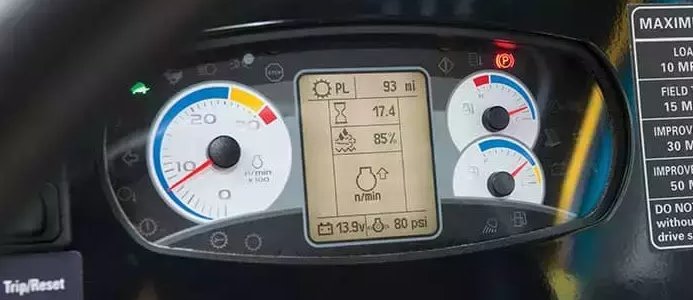

ADDITIONAL INSTRUMENTS KEEP YOU UP TO DATE

|

|

Overall length (in. (cm)) |

375 (953) |

|

Loader raised, stabilizers off (in. (cm)) |

119 (302) |

|

Loader raised, stabilizers at widest position (in. (cm)) |

136 (345) |

|

Loader down, stabilizers at widest position (in. (cm)) |

164 (417) |

|

Overall height (in. (cm)) |

176 (447) |

|

Overall height to top of stabilizers (in. (cm)) |

169 (429) |

|

Clearance needed to unload (in. (cm)) |

with 14 in x 18 in (36 cm x 46 cm) bales: 202 (513) - with 16 in x 18 in (41 cm x 46 cm) bales: 210 (533) |

|

Front axle (in. (cm)) |

9 5/8 (24) |

|

Rear axle (in. (cm)) |

10 (25) @ diff. housing, 6 (15) at leaf spring U-bolts |

|

Front axle (in. (cm)) |

80.25 (206) |

|

Rear axle (in. (cm)) |

75 (191) |

|

Wheelbase (in. (cm)) |

176 (447) |

|

Total with fuel, oil, and coolant (lbs. (kg)) |

18488 (8386) |

|

Gross vehicle weight (lbs. (kg)) |

33000 (14969) |

|

Weight box (optional) (lbs. (kg)) |

106 (48) empty; 600 (275) full |

|

Maximum power at rated speed (hp (kW)) |

190 (142) |

|

Aspiration |

Turbocharged & after cooled |

|

Number of cylinders / displacement (cu. in. (L)) |

6 / 408 (6.7) |

|

Type |

Allison 2500 RDS (Rugged Duty Service), 5-speed automatic |

|

Type |

Dana Spicer 22065T, 2-speed w/ locking rear differential |

|

Front |

4x70 Quadratic (4 piston) disc brakes, 15 in / 38 cm |

|

Rear |

4x70 Quadratic (4 piston) disc brakes, 15-3/8 in / 39 cm |

|

Type |

Dual: open center and closed center |

|

Pump type/system served |

Gear/Power steering, brake booster, park brake |

|

Maximum flow (gpm (Lpm)) |

7.0 (26.5) |

|

Relief pressure (psi (bar)) |

2300 (159) |

|

Pump type/system served |

Gear/Hydraulic motors |

|

Maximum flow (gpm (Lpm)) |

18 (70) |

|

Relief pressure (psi (bar)) |

2300 (159) |

|

Pump type/system served |

Load-sensing variable piston/cylinders |

|

Maximum flow (gpm (Lpm)) |

31.5 (119) |

|

Relief pressure (psi (bar)) |

2050 (141) |

|

Standby pressure (psi (bar)) |

180 (12.4) |

|

Front |

385/65R 22.5 Tubeless |

|

Rear |

445/50R 22.5 Tubeless |

|

Sizes capable - Height x Width x Length (in. (cm)) |

14 x 18 x 36-41 (35 x 46 x 91-104) and 16 x 18 x 36-41 (41 x 46 x 91-104) |

|

Optimum length of bale for best tie-tier (in. (cm)) |

38 (97) [for 14 x 18 (35 x 46) bales] or 40 (102) [for 16 x 18 (41 x 46) bales] |

|

14 in x 18 in x 36-41 in (36 cm x 46 cm x 91-104 cm) |

161 |

|

16 in x 18 in x 36-41 in (41 cm x 46 cm x 91-104 cm) |

161 |

|

16 in x 18 in x 44-48 in (41 cm x 46 cm x 112-122 cm) |

N/A |

|

3-Tie bales (all sizes) x 46 in (117 cm) |

N/A |

|

3 ft x 3 ft x 8 ft (91 cm x 91 cm x 244 cm) |

15 (with Mil-Stak® attachment) |

|

3 ft x 4 ft x 8 ft (91 cm x 122 cm x 244 cm) |

10 (with Mil-Stak® attachment) |

|

14 in x 18 in x 36-41 in (36 cm x 46 cm x 91-104 cm) (lbs. (kg)) |

50 - 75 (23 - 34) |

|

16 in x 18 in x 36-41 in (41 cm x 46 cm x 91-104 cm) (lbs. (kg)) |

70 - 90 (32 - 41) |

|

16 in x 18 in x 44-48 in (41 cm x 46 cm x 112-122 cm) (lbs. (kg)) |

N/A |

|

3-Tie bales (all sizes) x 46 in. (117 cm) (lbs. (kg)) |

N/A |

|

Maximum weight of load (lbs. (kg)) |

14512 (6583) |

|

Maximum height (in. (cm)) |

162 (411), with 16 in x 18 in (41 cm x 46 cm) bales |

|

Maximum width (in. (cm)) |

84 x 123 (213 x 312) with 14 in x 18 in (36 cm x 46 cm) bales, 96 x 123 (244 x 312) with 16 in x 18 in (41 cm x 46 cm) bales |

|

Fuel tank (gal. (L)) |

69 (261) |

|

DEF tank (gal. (L)) |

12.4 (47) |