Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

New Holland Flexi-Coil® P Series Air Carts - Flexi-Coil® P4760

|

COMPARTMENTS 4 CAPACITY 760 BUSHELS | |

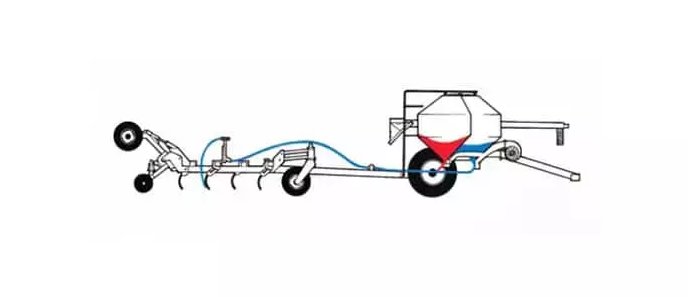

NEW, LARGER TOW-BETWEEN AIR CARTSNew P3720 and P4760 tow-between air cart models provide 30% greater capacity and feature a new hydraulic hitch jack for faster and easier tractor hook-up. A new ladder design provides exceptional operator access, whether the tractor is equipped with tracks, duals or triples. | |

NORMAL CAPACITIES, OUTSTANDING FEATURESChoose from a variety of P Series models with two, three or four tanks and tank sizes ranging from 350 to 950 bushels. Large tanks increase carrying capacity by 65% over previous models, so you can cover 160 acres with a single fill. | |

VARIABLE-RATE APPLICATIONFor maximum precision as field conditions change you can vary application rates using pre-loaded prescription maps. GPS position is communicated to the rate controller, which varies application rates by zone based on prescription-map criteria such as soil pH, fertility and irrigation. | |

ULTIMATE BLENDING FLEXIBILITYFlexi-Coil® P Series air carts let you apply seed, fertilizer or granular products in a single pass. This robust, reliable metering system provides greater flexibility to accurately apply product in either single- or double-shoot applications. |

LEADING METER CONTROL AND ACCURACYYou have one chance to get it right. For peace of mind, depend on the reliability and accuracy of P Series air carts with industry-leading, multi-patented meter control. |

IMMS: INTELLIRATE™ MODULAR METERING SYSTEM

|

TESTED IMMS DURABILITYThe IntelliRate™ modular metering system (IMMS) is engineered for the long haul. We performed rigorous and repetitive testing both in the laboratory and in the field to ensure you receive many years of maintenance-free operation. IMMS system durability was put to the test over many years and acres using different products, in different environments and temperatures for your peace of mind. |

STANDARD-EQUIPPED VARIABLE RATE APPLICATION CONTROLFor maximum precision, you can vary application rates using pre-loaded prescription maps to better manage field variability. GPS position is communicated to the rate controller which varies application rates by zone, based on your prescription map criteria. |

ULTIMATE IN BLENDING FLEXIBILITY: DISTRIBUTE OR COMBINE ANY TANK TO ANY RUN

|

INDUSTRY-LEADING TYPE B DISTRIBUTION SYSTEM FOR UNMATCHED ACCURACYWith a primary product division at the meter box and a secondary division on the drill, the Flexi-Coil system provides unmatched accuracy and is the preferred delivery system for air cart applications. |

EZ FLOW HEADERSEZ Flow distribution headers can significantly increase yields by providing unbeatable product flow and gentle seed handling, guiding seeds through primary and secondary lines and reducing seed cracking or scarring for better germination and higher yields. |

SINGLE-SHOOT DELIVERY

|

EXPANDED RATE RANGE WITH INCREASED ACCURACYWe’ve expanded your choice of application rates so you can set the ideal match for your needs today and tomorrow. In fact, this expanded range represents 15% higher and lower rates as compared to an equally configured P1000 Series cart. The IntelliRate™ modular metering system (IMMS) combined with dual product fans raises this bar to an all-new level with unmatched capacity combined with industry-leading accuracy. The exclusive patent-pending design allows for the same meter to be used for all product types. There are three-meter cartridges that can be quickly changed to accommodate various products and rates. |

MAKE THE MOST OF YOUR SEEDING WINDOWFlexi-Coil® P Series air carts help you make the most out of your time, eliminating waste and increasing your seeding and application efficiency. |

THE MOST ACCURATE SECTIONAL CONTROL AVAILABLE

|

|

Compartments |

4 |

|

Chassis |

Durable High Strength Frame with Powder Coat Paint Finish |

|

Configuration |

Tow-Behind |

|

Main Tank Material |

Polyethylene Roto-molded |

|

Auxiliary Tank Material |

- |

|

Total (bu. (L)) |

760 (26782) |

|

Tank 1 (bu. (L)) |

230 (8105) |

|

Tank 2 (bu. (L)) |

170 (5991) |

|

Tank 3 (bu. (L)) |

325 (11453) |

|

Auxiliary Tank, (bu. (L)) |

35 (1233) |

|

Type |

Type B system - Primary division at meter and secondary division on seeding implement |

|

Meter Drive System |

Intellirate™ Modular Metering System - IMMS |

|

Variable Rate Metering |

Standard Equipped |

|

Single Shoot |

- |

|

Double Shoot (Optional) |

- |

|

Sectional Control |

Optional 8 run/Expandable up to 12 run |

|

Monitor System |

IntelliViewTM IV or ISO 11783 (ISOBUS Compliant) Display is required for operation |

|

Bin Level Sensors |

Standard |

|

Tank Pressure Sensors |

Optional |

|

In-Tank Cameras |

Optional |

|

Rear-view Camera |

Optional |

|

Wireless Conveyor Control |

Standard |

|

Pneumatic Fill |

Standard |

|

Standard Auger |

- |

|

Deluxe Auger |

- |

|

Conveyor |

Standard |

|

Base Front |

650/75R38 172A8 R-1W Single |

|

Front High Float (Optional) |

800/65R32 167A8 R-1W Single |

|

Base Rear - TBH |

800/70R38 CHO 181A8 R-1W Single |

|

Rear High Float - TBH (Optional) |

800/70R38 176A8 R-1W Dual |

|

Base Rear - TBT |

- |

|

Rear High Float - TBT (Optional) |

- |

|

Height (in. (mm)) |

210 (5340) |

|

Height (Platform Railing Down) (in. (mm)) |

188 (4764) |

|

Width (in. (mm)) |

233 (5909) |

|

Tow-Behind Length (in. (mm)) |

452 (11491) |

|

Tow-Between Length (in. (mm)) |

- |

|

Weight, Tow-Behind (empty) (lbs. (kg)) |

26,420 (32579) |

|

Weight, Tow-Between (empty) (lbs. (kg)) |

27,845 (12630) |