Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

Salford MAGNASPREAD PLUS+ SPINNER SPREADER

| Build for efficiency and performance, Salford’s BBI MagnaSpread Plus+ combines the use of one spreader to maximize both fertilizer and lime application widths, saving you time and money. This machine has the capacity to spread dry fertilizer up to 120’ and lime up to 60’ – all with one machine. The new MagnaSpread Plus+ builds on the industry leading performance of Salford’s BBI MagnaSpread by adding new technology to maximize your investment. |

|

12' SINGLE AXLE MAGNASPREAD PLUS+ STANDARD FEATURES • Hydraulic Binary Manifold with pilot operated relief, manual flow controls for spinner and conveyor |

|

20' TANDEM AXLE MAGNASPREAD PLUS+ STANDARD FEATURES • Hydraulic Binary Manifold with pilot operated relief, manual flow controls for spinner and conveyor |

|

Salford BBI spreaders are designed to save time and cost of application by achieving industry leading application widths. In order to maximize the application width with each material the MagnaSpread Plus requires a spinner and flow divider change over. Switch from fertilizer application to lime application with two people in under 30 minutes! *Maximum application width varies by material quality. |

|

The MagnaSpread Plus uses tried and tested hopper designs, the high-clearance single axle 12 foot hopper or the tandem axle 20 foot hopper, equipped with Salford’s latest advancements in application technology. Engineering improvements make this spreader even more accurate and easy to set. The axle configurations help producers who need the widest application window or those looking for the maximum pay load. |

|

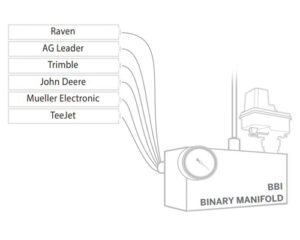

Patented hydraulics control system – connectivity to all major precision agriculture technology brands Variable Rate ready ISOBUS compatibility to most major precision control systems Multiple factory-installed systems available |

|

High quality JIC fittings & true hydraulic pipe GR Valve – increasing chain speed Hy-Torque manifold – increasing available spinner torque |

|

Series |

BBI | BBI |

|

Size |

264 cu-ft | 440 cu-ft |

|

Product type |

Pull Type Spinner Spreaders | Pull Type Spinner Spreaders |

|

Model Name Short |

MagnaSpread Plus | MagnaSpread Plus |

|

Model Name Long |

MAGNASPREAD PLUS+ 12' Single Axle Spreader | MAGNASPREAD PLUS+ 20' Tandem Axle Spreader |

|

Fertilizer |

YES | YES |

|

AG Lime |

YES | YES |

|

Litter |

NO | NO |

|

Organics |

NO | NO |

|

Seed |

NO | NO |

|

Other |

- | - |

|

Number of products applied, including optional hopper compartments |

1 | 1 |

|

Paint |

Standard Paint Color – Red |

Standard Paint Color – Red |

|

Hitch |

Standard: Cast Hitch for Pull Type Spreaders – includes Pintle and Clevis Hitch |

Standard: Cast Hitch for Pull Type Spreaders – includes Pintle and Clevis Hitch |

|

Jack |

Heavy-duty tongue jack | Heavy-duty tongue jack |

|

Tarp |

Standard: No Tarp |

Standard: No Tarp |

|

Tail Light |

Rear Tail Lights with Turn Signal, Side Markers |

Rear Tail Lights with Turn Signal, Side Markers |

|

Height |

- | - |

|

Weight |

- | - |

|

Hopper Size |

12′ High Profile Hopper 264 cu-ft |

20′ 96″ Wide Hopper 440 cu-ft |

|

Hopper Material |

Standard: 409 Stainless Steel, Painted |

Standard: 409 Stainless Steel, Painted |

|

Hopper Extensions |

Standard: No Extension Brackets |

Standard: No Extension BracketsOptional: 6″ extension brackets |

|

Hopper Gate Control |

Jack Operated Gate |

Jack Operated Gate |

|

Hopper Ladder |

- | - |

|

Hopper "Inverted V" |

Standard: Removeable Invertered V |

Standard: Removeable Invertered V |

|

Hopper Sight Window |

Standard Sight Window |

Yes |

|

PTO Drive |

Choice: 1000 RPM Series 6 CV 1 3/4 20 Spline |

Choice: 1000 RPM Series 6 CV 1 3/4 20 Spline |

|

Material Distribution Booms/Spinners/Air Line |

30″ dished spinner design for precision coverage |

30″ dished spinner design for precision coverage |

|

Application Swath Width |

Lime: Up to 50 feet Fert: Up to 120 feet |

Lime: Up to 50 feet Fert: Up to 120 feet |

|

Material Distribution Drive |

Standard: Self Contained PTO Hydraulics |

Standard: Self Contained PTO Hydraulics |

|

Metering Drive |

Tandem conveyor drive gearbox |

Tandem conveyor drive gearbox |

|

Primary Metering |

Standard: 30″ Belt-Over-Bar Chain |

Standard: 30″ Belt-Over-Bar Chain |

|

Primary Metering Minimum Output Rate |

- | - |

|

Primary Metering Maximum Output Rate |

- | - |

|

Secondary Metering |

N/A |

N/A |

|

Secondary Metering Minimum Output Rate |

- | - |

|

Secondary Metering Maximum Output Rate |

- | - |

|

Material Banding or Section Control |

N/A |

N/A |

|

Axle |

- |

|

Tire and Wheel Options |

- |

|

Monitors Options and Rate Control |

- |

|

Weigh System Option |

- |

| Name | Link |

| BBI Literature | Download |