Welcome to Ebert Welding LTD.

Ebert Welding LTD. is an authorized dealer for New Holland Agricultural, Salford Group, Gerber Gravity Bins, Farm-Fleet and Cub Cadet. We are also the Sur-Trac Snowmobile Trail Grooming Equipment and Trail Bridge manufacturer. Eberts' is proud to have talented fabricators and welders who are able to design, create or fix whatever it may be to suit your needs, with the help of a fully equiped shop.

Located in New Liskeard, Ontario, we serve Northeastern Ontario and Northwestern Quebec. Ebert Welding LTD. has a complete parts department and service department, including, a mobile service truck. Our mission is to serve the agricultural, trail grooming, mining and machining industries throughout the Northern Ontario-Quebec corridor. We are proud to support and sell brands such as Walco, HLA/Horst, SKF, NTN, KML, Hercules, Conventa, Canadian Farm Supply, Amcan, and so on.

Ebert Welding LTD. would be more then happy to help You to meet your needs, no matter what the industry may be.

Salford AB320AF APPLICATOR FOR AGCO FLOATERS

|

6700 AGCO Salford’s next-generation air boom applicator offers versatility, precision application and efficiency all in one complete package. Featuring Salford’s Valmar air boom technology, this self-propelled chassis mounted air boom offers a 90-foot application width with one of the largest hoppers on the market. This design offers greater capacity for fewer fill-ups, an easy-to-operate metering system and the most advanced air boom system available on the market today. The 6700 is ideal for broadcast application of granular fertilizer, granular chemicals, cover crops and micro-nutrients. |

|

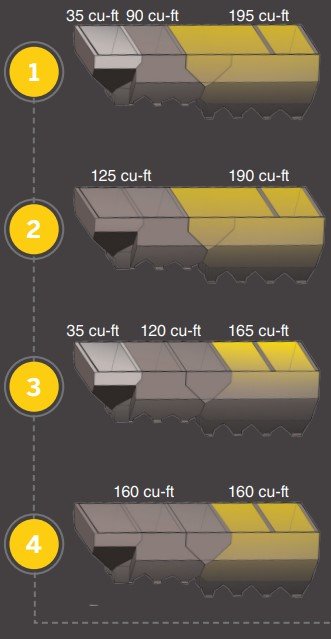

The new 6700 model is capable of applying one, two or three products at once with various hopper configurations. Empty hoppers can be adjusted in seconds with no tools or bin inserts required. The hoppers are made out of 409 stainless steel and can be painted to match your chassis. |

|

Salford’s latest 6700 model features Valmar’s Venturi metering design with proven reliability and simple maintenance. Set up for Raven® RCM, you can reduce application overlap and save on input costs with variable rate application and left / right section control. Compartments 1 and 2 are equipped with 304 stainless steel conveyors and the micro hopper uses a metering roller system to help accurately apply micro-nutrients, cover crops or granular herbicides while fertilizer is metered from the main hoppers. |

|

The 90-foot, bi-fold booms are built with 304 stainless steel and spring-protected break-away tips. Hydraulic boom suspension allows for greater in-field stability at higher operating speeds. The optional Raven UltraGlide AutoBoom® system can be added and calibrated to provide worry-free operation of the boom controls. |

|

Series |

Valmar |

|

Size |

320 cu-ft |

|

Product type |

Chassis Mount Air Boom Applicators |

|

Model Name Short |

AB320AF |

|

Model Name Long |

AB320AF Applicator for AGCO Floaters |

|

Fertilizer |

Yes |

|

AG Lime |

No |

|

Litter |

No |

|

Organics |

No |

|

Seed |

Yes |

|

Other |

Granular Herbicide |

|

Number of products applied, including optional hopper compartments |

3 |

|

Paint |

Yellow |

|

Hitch |

N/A |

|

Jack |

N/A |

|

Tarp |

Standard: No Tarp |

|

Tail Light |

Transport lighting and external LED work lights |

|

Height |

90" Unmounted |

|

Weight |

13,000 lbs |

|

Hopper Size |

320 cubic foot 3 compartment hopper |

|

Hopper Material |

Standard: 409 Stainless Steel, Painted |

|

Hopper Extensions |

N/A |

|

Hopper Gate Control |

N/A |

|

Hopper Ladder |

∙ Front ladder & platform |

|

Hopper "Inverted V" |

Yes |

|

Hopper Sight Window |

Yes |

|

PTO Drive |

Chassis Supplied |

|

Material Distribution Booms/Spinners/Air Line |

∙ 90 foot spread / 304 stainless steel |

|

Application Swath Width |

90 feet |

|

Material Distribution Drive |

10 inch Crary fan impellor with pwm control |

|

Metering Drive |

Hydrualic driven metering |

|

Primary Metering |

Dual, independently driven 16″ 304 stainless steel mesh chain conveyors (1 LH & 1 RH) |

|

Primary Metering Minimum Output Rate |

75 lbs/acre* at 10 mph, 65 lbs/cu-ft |

|

Primary Metering Maximum Output Rate |

1200 lbs/acre* at 10 mph, 65 lbs/cu-ft |

|

Secondary Metering |

Optional: Roller Meter System for Micro-Nutrient Compartment |

|

Secondary Metering Minimum Output Rate |

- |

|

Secondary Metering Maximum Output Rate |

- |

|

Material Banding or Section Control |

Left/Right |

|

Axle |

- |

|

Tire and Wheel Options |

- |

|

Monitors Options and Rate Control |

- |

|

Weigh System Option |

- |

| Name | Link |

| AGCO AB320AF Literature | Download |